Trommel Screen / Rotary Screen

Product Description

The trommel screen is a simple, efficient and economical solution to retrieve fine pieces of a wide range of materials such as ore, metals, and minerals. This method of screening not only reduces the time and manual effort in separating, but also increases the grade of the end product grade, while allowing for a rapid and large processing volume. The mining and quarrying equipment is designed for low operating costs and maintenance and high performance and production rates.

Other Images

Other Images

Technical Parameters of Trommel Screen

The trommel screen is a simple, efficient and economical solution to retrieve fine pieces of a wide range of materials such as ore, metals, and minerals. This method of screening not only reduces the time and manual effort in separating, but also increases the grade of the end product grade, while allowing for a rapid and large processing volume. The mining and quarrying equipment is designed for low operating costs and maintenance and high performance and production rates.

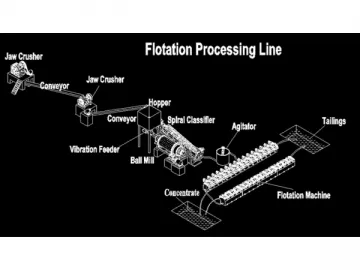

Working Principle

Raw materials are fed into the drum from the storage hopper and tossed in the air by the speed of rotation and washed as water is flushed in. This action is repeated with each revolution along the wall of the rotary screen. The finer ore passes through the roller screen while large ore pieces tumble towards an exit at the back of the drum. The finer pieces of mineral ore is passed through another channel for further processing in the centrifugal concentrator, spiral chute, or jig machine.

Technical Parameters of Trommel Screen

| Model | Capacity (t/h) | Power ( kw ) | Drum Diameter (mm) | Drum Length (mm) | Screen Mesh Size (mm) | Dimensions (mm) | Weight (T) |

| GT0510 | 1-3 | 1.5 | 500 | 1000 | <3~10 | 1800*1020 *1500 | 1.0 |

| GT1015 | 5-10 | 4.0 | 1000 | 1500 | 3000*1400 *2145 | 2.2 | |

| GT1020 | 15-25 | 5.0 | 1000 | 2000 | 3460*1400 *2145 | 2.8 | |

| GT1225 | 25-35 | 7.5 | 1200 | 2500 | 4146*1600 *2680 | 4.2 | |

| GT1530 | 35-50 | 11 | 1200 | 3000 | 4460*1900 *2820 | 5.1 | |

| GT1545 | 50-80 | 15 | 1500 | 4500 | 5960*1900 *3080 | 6.0 | |

| GT1848 | 80-120 | 22 | 1800 | 4800 | 6500*2300 *4000 | 7.5 | |

| GT2055 | 120-150 | 30 | 2000 | 5500 | 7500*2500 *4000 | 8.6 |

Scan QR to Read

Links:https://www.globefindpro.com/products/69748.html

Links:https://www.globefindpro.com/products/69748.html

Recommended Products