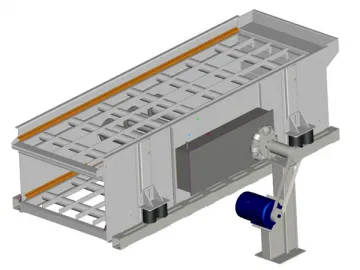

Vibrating Feeder

With a highly stable and efficient performance our GZD series of vibrating feeders uniformly conveys larger materials to crushers. A double eccentric vibration shaft ensures the equipment can withstand the impact of large materials falling on it for a long service life. The feeding machine has a plate structure, used for sand and rock production lines, and a grate structure which screens out coarser materials. Used alongside crushing equipment, the vibrating feeder is applicable in the metallurgy, coal, ore dressing, construction materials, chemical, and grinding compound industries.

Features

This series of vibrating feeders feature smooth vibration, reliable operation, low noise, low energy consumption, long service life and easy maintenance. Because of its lightweight and small size, the industrial mining equipment is easy to install and its closed structure prevents dust from spreading.

Working principle

The GZD series of vibrating feeders is made of a feeder groove, exciter, spring bearing, and gears. The exciter, which makes the feeding equipment vibrate, is made of two eccentric shafts and gears and the motor that drives the active axis. The upper gear of the active axis drives the passive-axis, alternating with active and passive axis rotation, which vibrates the machine’s body and lets materials flow continuously.

Specifications

| Model | Trough Size (mm) | Max Feeding Size (mm) | Capacity (t/h) | Power ( kw ) | Overall Dimensions (mm) | Weight (kg) |

| GZD850x3000 | 850x3000 | 400 | 80-120 | 7.5 | 3110x1800x1600 | 3895 |

| GZD960x3800 | 960x3800 | 500 | 120-210 | 11-15 | 3850x1950x1630 | 3980 |

| GZD1100x4200 | 1100x4200 | 580 | 200-430 | 11-15 | 4400x2050x1660 | 4170 |

| GZD1100x4900 | 4900x1100 | 580 | 280-500 | 15-18.5 | 5200x2050x1700 | 4520 |

| GZD1300x4900 | 4900x1300 | 650 | 450-600 | 18.5-22 | 5200x2350x1750 | 5200 |

Links:https://www.globefindpro.com/products/69757.html