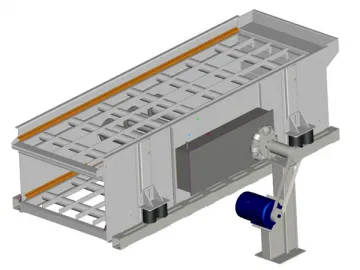

Triple Pass Rotary Drum Dryer

The triple pass rotary drum dryer prolongs the time of drying, improving production capacity by 50-80% compared to that of monocular dryers.

Technical Parameters

Technical Parameters

Features

1. The final percentage of moisture for the slag is ensured to be below 0.5%, making the industrial dryer ideal for dry-mixed mortar and slag powder production lines.

2. The self-heating efficiency of the cylinder can reach as high as 70%.

3. Coal, gas or oil can be used as fuel for drying lumps, granules and powdery materials with a granularity below 20mm.

4. Compared with monocular dryers, our rotary drum dryer takes up 50% less floor space and uses 60% less energy.

5. The final water content index can be easily adjusted according to need.

6. The triple drum dryer doesn't need a rack wheel but uses a riding wheel for transmission.

| Item/Unit/Model | Φ2.5×7m | Φ2.7×7m | Φ3.0×7.0m | Φ3.2×7.0m | Φ3.6×8m |

| Diameter of outer cylinder (m ) | 2.5 | 2.7 | 3.0 | 3.2 | 3.6 |

| Length of outer cylinder ( m ) | 7 | 7 | 7.0 | 7.0 | 8 |

| Cylinder volume (m³ ) | 16.63 | 16.63 | 52.678 | 52.678 | 81.38 |

| Rotating speed of cylinder (rpm ) | 4-10 | 4-10 | 4 -10 | 4 -10 | 4 -10 |

| Initial moisture of slag (% ) | 10-12 | 10-12 | 10-12 | 10-12 | 10-12 |

| Final moisture of slag (% ) | 1 | 1 | 1 | 1 | 1 |

| Initial moisture of yellow ground (% ) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| Final moisture of yellow ground (% ) | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 | 0.5-1 |

| Highest intake air temperature (℃ ) | 700-750 ℃ | 700-750 ℃ | 700-750 ℃ | 700-750 ℃ | 700-750 ℃ |

| Production capacity (T/h ) | Yellow sand25-30 Slag20-25 | Yellow sand30-35 Slag25-30 | Yellow sand35-40 Slag30-35 | Yellow sand45-50 Slag35-40 | Yellow sand65-70 Slag60-65 |

| Motor type | Y2-132m-4E | Y2-132m-4E | Y2-160m-4 | Y2-160m-4 | Y2-160m-4 |

| Motor power (kw ) | 7.5×2 | 11×2 | 7.5×4 | 7.5×4 | 15×4 |

| Reducer type | XWD7-23-11W | XWD7-23-11W | XWD6-23-7.5KW | XWD6-23-7.5KW | XWD8-23-15KW |

| Velocity ratio of reducer | 29 | 29 | 29 | 29 | 29 |

Scan QR to Read

Links:https://www.globefindpro.com/products/69759.html

Links:https://www.globefindpro.com/products/69759.html

Recommended Products

Hot Products