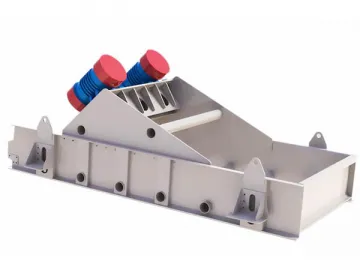

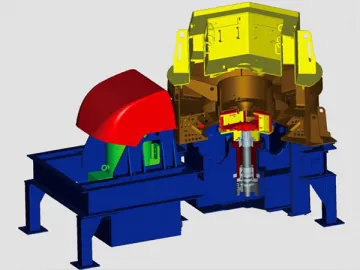

Ceramic Ball Mill

Features

1) High quality

2) High efficiency

3) Low energy consumption

Structure

The ceramic ball mill is a horizontal cylinder rotating device that runs along an exterior track. It’s made of a feed system, dispensing system, rotator and drive system (made of a reducer, small driving gear, electric motor and electric control), and two chambers. Through a hollow spiral shaft, material is sent to the milling machine’s first chamber, where there are ladder liners or corrugated linings, with steel balls of different specifications. When the cylinder rotates, centrifugal force rotates the steel balls, which grinds materials as they roll around. After this first coarse grinding, materials enter the mineral processing machinery's second chamber with a flat lining board and steel balls for fine grinding.

Specifications of Ceramic Ball Mill

| Model | Capacity (t) | Speed of Bucket (r/min) | Motor Power ( kw ) |

| 600×700 | 0.05 | 50 | 2.2 |

| 800×600 | 0.075 | 42 | 3 |

| 900×1200 | 0.2 | 38.5 | 5.5 |

| 1300×1500 | 0.5 | 33 | 7.5 |

| 1500×1800 | 1.2 | 28.5 | 11 |

| 1800×2000 | 1.5 | 24 | 15 |

| 2600×2800 | 5 | 16.5 | 37 |

| 3000×3800 | 10 | 14.5 | 55 |

| 3200×4600 | 15 | 13.5 | 75 |

| 3400×6600 | 18 | 13 | 135 |

Links:https://www.globefindpro.com/products/69783.html