Tower Crane QTZ125

The QTZ125 hammerhead tower cranehas advanced technical parameters with a maximum radius of 60/63/65m and a maximum height of 181m with mast sections and anchorages. If customers need, we can design this self-erecting craneto reach 200m.

The hammerhead tower crane can come in stationary, external climbing and inner climbing models that can be used in different construction sites. It has a high speed for its trolley and slewing mechanisms and are easily adjusted without compromising the construction machinery's stability.

With an imported electronic control system, the top slewing crane has a service life that is three times longer than other cranes on the domestic market, and has fewer errors and is easier to maintain.

The tower crane features a lightweight structure in which the mast sections have integral angle steel welding that is safe and reliable. Advanced mechanical or Mechatronics products work efficiently even in poor conditions to keep the tower cranes working safely at top performance.

Advanced Electronic Appliances

1) Excellent safety devices including weight limiters, moment limiters, height limiters, radius limiters, slewing limiters, and slewing and trolleying brakes

2) Device to prevent the wire ropes and shafts from breaking

3) The rope controlling system of hoisting mechanism

| Rated Lifting Torque | kN.m | 1250 | ||

| Maximum Lifting Load | t | 10 | ||

| Work Radius | m | 3 ~ 60/63/65 | ||

| Lifting Height | Independent | 50 | ||

| Attaching | 180 | |||

| Lifting Speed | 2-falls | m/min | 101.5/51.83 | |

| 4-falls | 49.11/25.08 | |||

| Slewing Speed | r/min | 0.65 | ||

| Trolleying Speed | m/min | 58.6/29.3/8.79 | ||

| Climbing Speed | 0.4 | |||

| Minimum Stable Falling Speed | ≤5 | |||

| Machine Dimension | Chassis | m | 8×8 | |

| Total Height | Independent | 60 | ||

| Attaching | 190 | |||

| Tip of jib to slewing center | 63.372 | |||

| Tip of balanced jib to slewing center | 14.82 | |||

| Self-weight of whole crane | Structure Weight | Independent | t | 63.508 |

| Attaching | 125.628 | |||

| Balance Weight | 20.8 | |||

| Total Capacity of Motor | kW | 60.85 | ||

| Allowable Work Temperature | ℃ | -20 ~ 40 | ||

| Power Supply Parameter | 50Hz | ~ 380V±10% | ||

Detailed Technical Parameters of Tower Crane Mechanisms

| Work grade of mechanisms | Hoisting mechanism | M5 | |||

| Slewing mechanism | M4 | ||||

| Trolleying mechanism | M4 | ||||

| Radius (m) | Min. 2.5 | Max. 60/63/65 | |||

| Hoisting Height (m) | Independent | Attaching | |||

| 50 | 181.3 | ||||

| Max. Load (t) | 8 | ||||

| Hoisting mechanism | Type | QEW-880D | |||

| Falls | α=2 | α=4 | |||

| Load and speed (t and m/min) | 2/80 | 4/40 | 4/40 | 8/20 | |

| Power ( Kw ) | 30/30 | ||||

| Trolleying mechanism | Speed (m/min) | 0~55 | |||

| Power ( Kw ) | 5.5 | ||||

| Slewing mechanism | Speed (r/min) | 0~0.8 | |||

| Power ( Kw ) | 4.0×2 | ||||

| Jacking mechanism | Speed (m/min) | 0.58 | |||

| Power ( Kw ) | 7.5 | ||||

| Work pressure ( MPa ) | 25 | ||||

| Balanced weight | Jib (m) | 53 | 58 | 63 | |

| Load (t) | 17 | 18.5 | 20 | ||

| Total power (kW) | 43.5 (without hydraulic system) | ||||

| Work temperature ℃ | -20~ 40 | ||||

| Type | Unit | QEW-880D | |||||||||

| Hoisting mechanism | Max. Tractive force | N | 24444 | ||||||||

| Steel wire rope | Specification | 35 ´ 7-14-1770 or 6T29Fi IWR-14-1670 | |||||||||

| Max. Line speed | m/min | 160 | |||||||||

| Drum | Speed | r/min | 91.6 | ||||||||

| Capacity | m | 300(4 layers) | |||||||||

| Motor | Type | YZRDW250M1-4/8 | |||||||||

| Power | kW | 30/30 | |||||||||

| Speed | r/min | 1425/725 | |||||||||

| Type of reducer | ZQ60-16-IV-CA | ||||||||||

| Brake | Type | YWZ3 -315/90-16 | |||||||||

| Braking moment | N.m | 1250 | |||||||||

| Trolleying mechanism | Type | Unit | BP55 | ||||||||

| Max. Tractive force | N | 9000 | |||||||||

| Steel wire rope | Spec. | 6 ´ 19-9.3-1700- | |||||||||

| Max. Line speed | m/min | 55 | |||||||||

| Length | 53m jib | m | Steel wire rope Ⅰ | 106 | Steel wire rope Ⅱ | 64 | |||||

| 58m jib | m | 116 | 69 | ||||||||

| 63m jib | m | 126 | 74 | ||||||||

| Speed of drum | r/min | 0~ 32.7 | |||||||||

| Motor | Type | YEJ132S-4B5 | |||||||||

| Power | kW | 5.5 | |||||||||

| Speed | r/min | 1440 | |||||||||

| Ratio of reducer | 47.87 | ||||||||||

| Braking moment | N. m | 38.7 | |||||||||

| Type | Unit | HPW40 | |||

| Slewing mechanism | Motor | Type | YTW112M-4B5 | ||

| Power | kW | 4.0 | |||

| Speed | r/min | 0~1440 | |||

| Reducer | Type | XX4-100.195C | |||

| Transmission ratio | 195 | ||||

| Output torque | N.m | 10000 | |||

| Output speed | r/min | 0~4.923 | |||

| Parameters of output gear | Modulus m | 12 | |||

| Teeth z | 16 | ||||

| Modification coefficient x | 0.5 | ||||

| Total ratio of main engine | 1596.56 | ||||

| Speed | 0~0. 8 | ||||

| Jacking mechanism | Motor | Power | kW | 7.5 | |

| Speed | r/min | 1440 | |||

| Hydraulic pump station | Flow | l/min | 14 | ||

| Work pressure | MPa | 25 | |||

| Jacking cylinder | Dia . of cylinder and piston rod | mm | 160/110 | ||

| Max. Jacking force | t | 50 | |||

| Jacking speed | m/min | 0.58 | |||

Links:https://www.globefindpro.com/products/70279.html

-

Diesel Powered Concrete Pump HBT80C-16-154RS

Diesel Powered Concrete Pump HBT80C-16-154RS

-

Sandwich Panel Production Line

Sandwich Panel Production Line

-

Trailer Mounted Concrete Pump HBT60.11.90S

Trailer Mounted Concrete Pump HBT60.11.90S

-

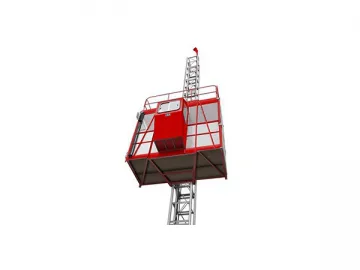

Construction Hoist SC100

Construction Hoist SC100

-

Tower Crane QTZ63

Tower Crane QTZ63

-

Concrete Mixer

Concrete Mixer

-

Concrete Batching Plant HZS50

Concrete Batching Plant HZS50

-

Concrete Pump HBT80-16-110S

Concrete Pump HBT80-16-110S

-

Concrete Pump

Concrete Pump

-

Pipe Fitting, Tee Adapter

Pipe Fitting, Tee Adapter

-

Plastic Injection Mold (Motorcycle Parts Molds)

Plastic Injection Mold (Motorcycle Parts Molds)

-

Stamping Die

Stamping Die