Trailer Mounted Concrete Pump HBT60.11.90S

The HBT series of trailer mounted concrete pumps is a high-tech product using internationally advanced technology and our expert design and production experience. With excellent technical performance, standard configuration and high reliability, the affordable concrete machinery is widely applied in highway, construction, and water-powered projects.

Characteristics of the Trailer Mounted Concrete Pump

1. All hydraulic hoses and couplers are imported.

2. The reverse control is electrically-hydraulically driven. The electric part is controlled by PLC, which is reliable and accurate.

3. The counterforce on the specially designed “S” valve is received by the hopper wall for the concrete pump’s long service life.

4. Reliable master oil cylinder and concrete cylinder can operate for at least 30,000 m3.

5. The trailer mounted cement pump’s main electric elements come from Schneider, OMRON, Siemens, and LG.

6. The open loop of the hydraulic system is air cooled to keep the oil temperature below 60 ℃ for stable operation.

7. Control mode: manual operation

| Parameter | Unit | HBT60.11.90S |

| Max. Theoretical. Concrete Output capacity | m³/h | 43/73 |

| Max. Delivery Pressure | mpa | 32 |

| Max. Theoretical Horizontal Delivery Distance | m | 1200 |

| Max. Theoretical Vertical Delivery Distance | m | 270 |

| Main Oil Pump:Cylinder Diameter/Rod D × Stroke | mm | φ125/1650 |

| Concrete Delivery Cylinder: Diameter × Stroke | mm | φ200×1650 |

| Diesel Engine Power | kw | 90 |

| Rated Rotating Speed | r/m | 1480 |

| Hopper Capacity | L | 800 |

| Hopper Height | mm | 1400 |

| Oil Tank Capacity | L | 500 |

| Hydraulic Circuit Form | Opened-circuit | |

| Delivery Valves Style | S-valve (Totally Cast) | |

| Max. Grain Diameter | mm | Pebble:50 Crushed Stone:40 |

| Overall Dimension L*W*H | mm | 6100×2100×2300 |

| Total Weight | kg | 6000 |

Links:https://www.globefindpro.com/products/70283.html

-

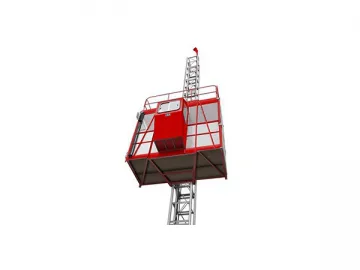

Construction Hoist SC100

Construction Hoist SC100

-

Tower Crane QTZ63

Tower Crane QTZ63

-

Concrete Mixer

Concrete Mixer

-

Construction Hoist SC100-100

Construction Hoist SC100-100

-

Plastic Engineer Mold (Pipe Fitting Molds)

Plastic Engineer Mold (Pipe Fitting Molds)

-

Tower Crane QTZ260

Tower Crane QTZ260

-

Sandwich Panel Production Line

Sandwich Panel Production Line

-

Diesel Powered Concrete Pump HBT80C-16-154RS

Diesel Powered Concrete Pump HBT80C-16-154RS

-

Tower Crane QTZ125

Tower Crane QTZ125

-

Concrete Batching Plant HZS50

Concrete Batching Plant HZS50

-

Concrete Pump HBT80-16-110S

Concrete Pump HBT80-16-110S

-

Concrete Pump

Concrete Pump