Automatic Welding Machine

Our automatic welding machine is equipped with swallowtail-typed genevawheel, thus improving stability. 3 axis mechanical tracking device and rotating tracking device can make sure that welding torch is at the correct position. And production time gets reduced because welding even can be done when the welding torch is moving back to its staring point.

Technical Parameters

| Model | YZA |

| Web size(mm) | 200-1200 |

| Flange size(mm) | 200-800 |

| H beam length(mm) | 4000-15000 |

| Welding machine model | 2 sets of 1000 automatic submerged arc welding machine |

| Welding type | Fillet weld |

| Welding speed(m/min) | 0.15-2.5 |

| Track gauge(mm) | 4000/5000 |

| Power ( Kw ) | 13KW(not include welding equipment) |

Our automatic welding machine mainly consists of gantry frame, rolling device, welding torch tracking device, flux collecting system, electric control system and submerged arc welding equipment. The gantry frame is the main body and the strength and rigidity are carefully designed to achieve advanced and strong configuration. Main parts have been through stress relief treatment after welding so that our machine can work reliably for a long time. Two AC motors drive the machine by means of frequency conversion technology and special device is used to keep gantry frame moving steadily and safely. High precision rectangular guides and adjustable eccentric wheels can ensure that welding head can move steadily. The motor and reducer as well as gear rack transmission system can make sure that different models of structure steel can be welded steadily.

Links:https://www.globefindpro.com/products/70346.html

-

Side Beam Welding Machine

Side Beam Welding Machine

-

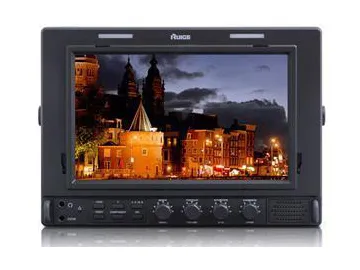

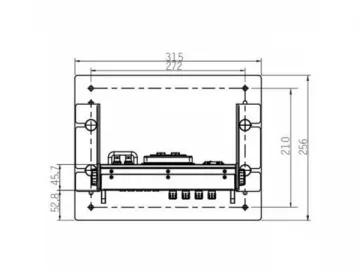

Jib Monitor, TL-S900YHD

Jib Monitor, TL-S900YHD

-

Assembly Machine

Assembly Machine

-

Gantry Type Automatic Welding Machine

Gantry Type Automatic Welding Machine

-

Edge Milling Machine

Edge Milling Machine

-

TL-B1730HD Desktop 17.3 Inch Broadcast Monitor, LCD Monitor

TL-B1730HD Desktop 17.3 Inch Broadcast Monitor, LCD Monitor

-

TL-701HD 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

TL-701HD 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

-

Desktop Monitor, TL-P1700HD

Desktop Monitor, TL-P1700HD

-

Jib Monitor, TL-1040YHD

Jib Monitor, TL-1040YHD

-

Viewfinder

Viewfinder

-

Automatic Welding Production line

Automatic Welding Production line

-

TL-701HDA 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

TL-701HDA 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor