Side Beam Welding Machine

YZC side beam welding machine is equipped with imported AC frequency converter, works steadily and can return fast, thus reducing much production time. 3-axis mechanical tracking device can track welding seam automatically to make sure that the welding seam is at the correct position to improve welding quality. The main machine and welding equipment are controlled together and automatic flux collector can collect flux automatically, thus improving efficiency greatly. Four wheels are driven synchronized so that side beam welding device can move smoothly and steadily.In order to weld workpiece of different diameters, there is an opening on the worktable through which operator can watch the welding seam clearly. And our side beam welding machine need small area.

Technical Parameters

| Model | YZC |

| Web size(mm) | 200-2000 |

| Flange size(mm) | 200-800 |

| H beam length(mm) | 4000-15000 |

| Welding machine model | 1set of MZ-1000 automatic submerged arc welding equipment |

| Welding type | Fillet weld |

| Welding speed (m/min) | 0.3-3 |

| Return speed (m/min) | 4.5 |

| Track gauge(mm) | 1150 |

| Power ( Kw ) | 2.2 (not include welding machine power) |

Links:https://www.globefindpro.com/products/70347.html

-

Jib Monitor, TL-S900YHD

Jib Monitor, TL-S900YHD

-

Assembly Machine

Assembly Machine

-

Gantry Type Automatic Welding Machine

Gantry Type Automatic Welding Machine

-

Edge Milling Machine

Edge Milling Machine

-

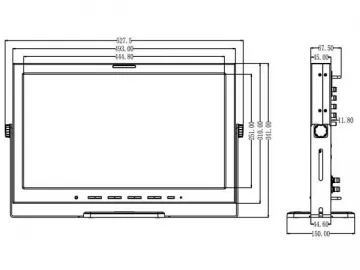

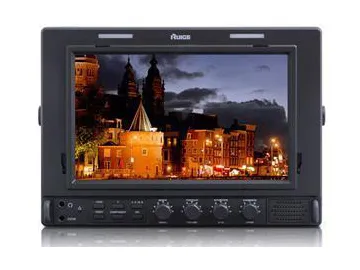

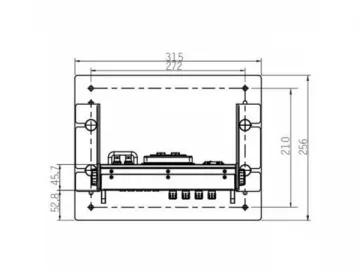

TL-B1730HD Desktop 17.3 Inch Broadcast Monitor, LCD Monitor

TL-B1730HD Desktop 17.3 Inch Broadcast Monitor, LCD Monitor

-

Desktop Monitor, TL-S2000HD

Desktop Monitor, TL-S2000HD

-

Automatic Welding Machine

Automatic Welding Machine

-

TL-701HD 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

TL-701HD 7 Inch LCD Small Screen On Camera Monitor/ Field Monitor

-

Desktop Monitor, TL-P1700HD

Desktop Monitor, TL-P1700HD

-

Jib Monitor, TL-1040YHD

Jib Monitor, TL-1040YHD

-

Viewfinder

Viewfinder

-

Automatic Welding Production line

Automatic Welding Production line