Hydraulic Straightening Machine

Hydraulic straightening machine is mainly used to straighten H-beam steel of thick flange. The hydraulic cylinder can provide big straightening force and driving torque. And hydraulic straightening equipment is widely used in large scale steel structure building, steel bridge, furnace frame, hydraulic structure and other industries due to high efficiency and good straightening quality.

Technical Specifications of Hydraulic Straightening Machine

| Model | YZJ60A | YZJ- 60B | YZJ80B |

| Flange width (mm) | 180-800 | 180-800 | 400-1000 |

| Flange thickness (mm) | ≤60 | ≤60 | ≤80 |

| Min. web width (mm) | 350 | 350 | 500 |

| Material | Q235A | 16Mn | 16Mn |

| Straightening speed (m/min) | 7.5 | 7.5 | 6 |

| Power ( Kw ) | 29.5 | 37 | 40 |

The upper roll device structure of the hydraulic straightening machine can bear bigger pressure and hydraulic cylinder can adjust the gap smoothly and reliably. The driving rolls are lifted up and down by hydraulic cylinders to protect rolls and make operation more convenient. The main roll and straightening rolls are made of high quality alloy steel and have been through heat treatment to eliminate flaws. The driving wheel made of 35LCrMo is forged and can work for a long time due to its high hardness up to HRC50-55.

In addition, the hydraulic pump is purchased from joint venture Ningbo Chuangli and high quality domestic sealing rings can work reliably for a long time. There is a filter in the pump so that all electric valves can work normally for a long time. And the scale can make sure that all operations are done precisely.

Links:https://www.globefindpro.com/products/70360.html

-

Welding Positioner

Welding Positioner

-

CNC Plasma Cutting Machine

CNC Plasma Cutting Machine

-

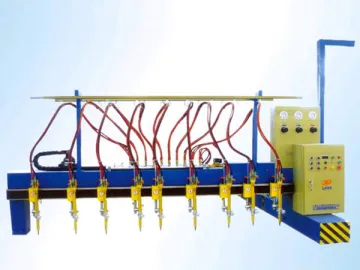

Flame Cutting Machine

Flame Cutting Machine

-

Steel Moving Machine

Steel Moving Machine

-

Cutting Machine

Cutting Machine

-

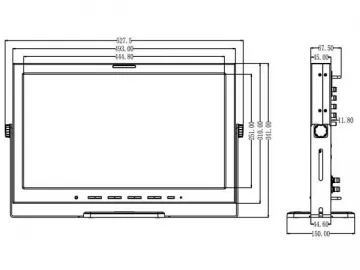

DSLR Field Monitor, TL-S500HD

DSLR Field Monitor, TL-S500HD

-

Desktop Monitor, TL-B2000HD

Desktop Monitor, TL-B2000HD

-

TLP890HD-2 Professional Rackmount 8.9 Inch Color Monitor, LCD Monitor

TLP890HD-2 Professional Rackmount 8.9 Inch Color Monitor, LCD Monitor

-

Adjustable Pipe Welding Turning Roll

Adjustable Pipe Welding Turning Roll

-

Rackmount Monitor , TL-B1730HD

Rackmount Monitor , TL-B1730HD

-

Desktop Monitor, TL-S2000HD

Desktop Monitor, TL-S2000HD

-

TL-B1730HD Desktop 17.3 Inch Broadcast Monitor, LCD Monitor

TL-B1730HD Desktop 17.3 Inch Broadcast Monitor, LCD Monitor