Welding Positioner

Welding positioner is made up of rotating table, tilting mechanism and electric control system. By tilting and rotating worktable suitable angles can be produced so that welding and assembling can be done. And the welding positioning equipment is featured as high rotation precision, low noise, excellent brake performance and stability. Frequency converter can produce the best worktable rotating speed so that welding positioner can work steadily. The worm reduction transmission system used to tilt worktable at a constant speed can provide large torque with angle range of 120 degrees. Due to different eccentric distances, long workpiece need a model whose worktable is longer. Standard model welding positioning device is suitable for all kinds odworkpiece and we can give suggestions given the workpiece shape, weight and manufacturing process. There are various rotation methods for you to choose from, including the tipping type, end-to-end rotation type, end-to-end elevation rotation type, end-to-end tilting type, double rotation type, etc.

Technical Parameters

| Model | YHB-01 | YHB-03 | YHB-06 | YHB-12 | YHB-30 | YHB-50 | YHB-100 |

| Rated load bearing (Kg) | 100 | 200 | 600 | 1200 | 3000 | 5000 | 10000 |

| Rotation speed (rpm) | 0.4 ~ 4 | 0.1 ~ 1 | 0.08 ~ 0.8 | 0.08 ~ 0.8 | 0.05 ~ 0.5 | 0.05 ~ 0.5 | 0.05 ~ 0.2 |

| Turning speed (rpm) | by hand | by hand | 0.55 | 0.4 | 0.23 | 0.14 | 0.14 |

| Turning angle (°) | 0-120 | 0-90 | 0-90 | 0-90 | 0-120 | 0-120 | 0-120 |

| Work table size (mm) | Φ 400 | Φ 600 | Φ 1000 | Φ 1200 | Φ 1400 | Φ 1500 | Φ 2000 |

| Rotating motor power (KW) | 0.18 | 0.18 | 0.37 | 0.75 | 1.5 | 2.2 | 3 |

| Turning motor power (KW) | / | / | 0.75 | 1.1 | 1.5 | 3 | 5.5 |

| Speed adjustment | AC variable frequency speed regulation | ||||||

| Maximum eccentric distance (mm) | 150 | 100 | 100 | 100 | 150 | 200 | 250 |

| Maximum center distance (mm) | 100 | 100 | 100 | 150 | 200 | 300 | 400 |

| Max. rotating diameter (mm) | Φ 600 | Φ 800 | Φ 1500 | Φ 2050 | Φ 2100 | Φ 2500 | Φ 3240 |

Product Showcase

Links:https://www.globefindpro.com/products/70361.html

-

CNC Plasma Cutting Machine

CNC Plasma Cutting Machine

-

Flame Cutting Machine

Flame Cutting Machine

-

Steel Moving Machine

Steel Moving Machine

-

Cutting Machine

Cutting Machine

-

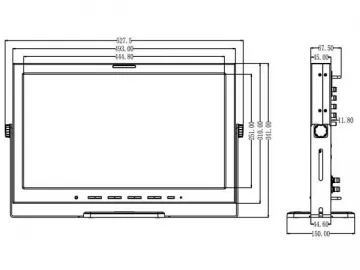

DSLR Field Monitor, TL-S500HD

DSLR Field Monitor, TL-S500HD

-

Ceramic Proppant

Ceramic Proppant

-

Hydraulic Straightening Machine

Hydraulic Straightening Machine

-

Desktop Monitor, TL-B2000HD

Desktop Monitor, TL-B2000HD

-

TLP890HD-2 Professional Rackmount 8.9 Inch Color Monitor, LCD Monitor

TLP890HD-2 Professional Rackmount 8.9 Inch Color Monitor, LCD Monitor

-

Adjustable Pipe Welding Turning Roll

Adjustable Pipe Welding Turning Roll

-

Rackmount Monitor , TL-B1730HD

Rackmount Monitor , TL-B1730HD

-

Desktop Monitor, TL-S2000HD

Desktop Monitor, TL-S2000HD