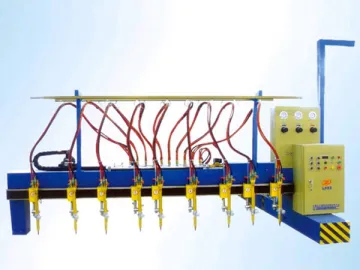

Flame Cutting Machine

Our flame cutting machine is equipped with high precision AC motor, helical gear reducer and gear rack transmission system to achieve better reliability and precision. Cutting flames can be positioned by the high precision lead screw and the linear guide of roll so that the cutting flames can be in the same vertical line to ensure high cutting precision.

Technical Parameters

| Track gauge | 4000mm | 5000mm | Roughness of surface | Ra12.5 | ||

| Cutting width | 3200mm | 4200mm | Repeatability precision | ±0.5 | ||

| Min. cutting width | Numerical control | 230mm | 230mm | Main pipe line | Oxygen | P=1MPa |

| Ethyne | P=0.1MPa | |||||

| Straight | 80mm | 80mm | ||||

| Voltage | AC220V±10% | |||||

| Cutting thickness | 6-100mm | 6-100mm | ||||

| Cutting speed | 0.05-1m/min | 0.05-1m/min | Frequency | 50Hz | ||

| Max. return speed | 4000mm /min | 4000mm /min | Total power | 1.5KW | ||

| Cutting precision | ±0.5mm/1000mm | |||||

The beam is wholly bended and has been through temper aging treatment to prevent deformation. High precision servo motor from Panasonic or Fuji company is installed to improve precision. Imported AC frequency inverter can adjust the cutting speed conveniently. The air pressure control box can conveniently control the air pressure. All imported adjusting valves and air pipes can ensure that our cutting machine can work normally for a long time. And air bus-bar can also be provided if it is necessary.

Links:https://www.globefindpro.com/products/70365.html

-

Steel Moving Machine

Steel Moving Machine

-

Cutting Machine

Cutting Machine

-

DSLR Field Monitor, TL-S500HD

DSLR Field Monitor, TL-S500HD

-

Ceramic Proppant

Ceramic Proppant

-

Fused Mullite

Fused Mullite

-

Field Monitor (for DSLR Camera)

Field Monitor (for DSLR Camera)

-

CNC Plasma Cutting Machine

CNC Plasma Cutting Machine

-

Welding Positioner

Welding Positioner

-

Hydraulic Straightening Machine

Hydraulic Straightening Machine

-

Desktop Monitor, TL-B2000HD

Desktop Monitor, TL-B2000HD

-

TLP890HD-2 Professional Rackmount 8.9 Inch Color Monitor, LCD Monitor

TLP890HD-2 Professional Rackmount 8.9 Inch Color Monitor, LCD Monitor

-

Adjustable Pipe Welding Turning Roll

Adjustable Pipe Welding Turning Roll