Gate Valve

The gate valve allows for a single flow of direction in order to provide backflow into the pipeline system, and is comprised of the body, bonnet, disc, stem, shaft and other parts.

Working Principle

For this non-return valve, the disc is opened under fluid pressure effect, and the fluid then flows through the valve body from the inlet to the outlet. When the inlet pressure is lower than the outlet pressure, the valve disc will be closed automatically due to the two directions of differential pressure and its own gravity, thus preventing backflow.

Advantage

1. This sluice valve achieves a fast and reliable opening/closing process, and it is easy for people to check how wide the gate is when opened. It is widely used in fire sprinkler systems and industrial systems. In this regard, it can also be called a fire protection gate valve or industrial gate valve.

2. Our gate valve is rubber coated in order to offer excellent sealing effect, meaning leakage and rusting is unlikely to occur.

3. The valve body is manufactured from ductile iron, making it lightweight and easy to install. The valve seat has a flat base in order to avoid dirt deposition and provides a better sealing effect at the same time.

4. A non-toxic epoxy resin is coated on the internal surface of the valve body in order to achieve excellent resistance to rusting and corrosion, making our ductile iron gate valve suitable for both drinking water and waste water.

5. The gate valve has a low operation torque and a long service life. Its seal rings can be replaced without stopping work, making on-site maintenance simple.

Application

Our gate valves are commonly used for on/off and throttling services for pipe systems in tap water, sewage, construction, chemical petrochemical, pharmaceutical, food, electricity, marine, and metallurgy industries.

| DN | L | D | DO | D1 | D2 | b | f | N-d | H |

| 40 | 140 | 150 | 130 | 110 | 88 | 19 | 3 | 4-19 | - |

| 50 | 150 | 165 | 130 | 125 | 102 | 19 | 3 | 4-19 | 202 |

| 65 | 170 | 185 | 130 | 145 | 122 | 19 | 3 | 4-19 | 222 |

| 80 | 180 | 200 | 150 | 160 | 138 | 19 | 3 | 8-19 | 250 |

| 100 | 190 | 220 | 185 | 180 | 158 | 19 | 3 | 8-19 | 303 |

| 125 | 200 | 250 | 185 | 210 | 188 | 19 | 3 | 8-19 | 351 |

| 150 | 210 | 285 | 195 | 240 | 212 | 19 | 3 | 8-23 | 411 |

| 200 | 230 | 340 | 225 | 295 | 268 | 20 | 3 | 8-23 | 498 |

| 250 | 250 | 395 | 245 | 350 | 320 | 22 | 3 | 12-23 | 579 |

| 300 | 270 | 445 | 285 | 400 | 378 | 24.5 | 4 | 12-23 | 679 |

| DN | L | H | D | D1 | D2 | b | n-d | W |

| 50 | 150 | 347 | 165 | 125 | 102 | 20 | 4-18 | 180 |

| 65 | 170 | 390 | 185 | 145 | 122 | 20 | 4-18 | 180 |

| 80 | 180 | 470 | 200 | 160 | 138 | 22 | 8-18 | 200 |

| 100 | 190 | 535 | 220 | 180 | 158 | 24 | 8-18 | 200 |

| 125 | 200 | 644 | 250 | 210 | 188 | 26 | 8-18 | 250 |

| 150 | 2210 | 739 | 285 | 240 | 212 | 26 | 8-22 | 280 |

| 200 | 230 | 936 | 340 | 295 | 268 | 26 | 8-22 | 300 |

| 250 | 250 | 1133 | 395 | 350 | 320 | 28 | 12-22 | 360 |

| 300 | 270 | 1330 | 445 | 400 | 370 | 28 | 12-22 | 400 |

Links:https://www.globefindpro.com/products/70467.html

-

Welded Ball Valve

Welded Ball Valve

-

Concrete Block Making Machine, QT3-15

Concrete Block Making Machine, QT3-15

-

Rubber Expansion Joints

Rubber Expansion Joints

-

Dry Granulator (for Pharmaceutical and Food Industry)

Dry Granulator (for Pharmaceutical and Food Industry)

-

Vacuum Paddle Dryer (with Two Hollow Shafts)

Vacuum Paddle Dryer (with Two Hollow Shafts)

-

Fire Protection Butterfly Valve

Fire Protection Butterfly Valve

-

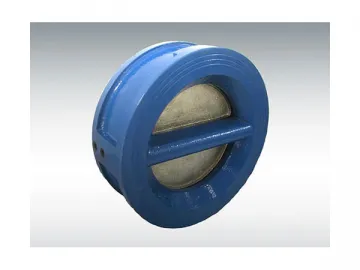

Wafer Check Valve

Wafer Check Valve

-

High Performance Butterfly Valve

High Performance Butterfly Valve

-

MW91b Cuffed Tracheostomy Tube

MW91b Cuffed Tracheostomy Tube

-

MW83b Silicone Foley Catheter

MW83b Silicone Foley Catheter

-

MW56 Nelaton Catheter

MW56 Nelaton Catheter

-

MW99c Laryngeal Mask Airway

MW99c Laryngeal Mask Airway