Concrete Block Making Machine, QT3-15

Technical Parameters of QT3-15 Concrete Block Making Machine

| Vibration frequency | 3800-4500 times/sub | ||||

| Total weight | 6200kg | ||||

| Overall dimension | 5130×3850×2600mm | ||||

| Installed capacity | 20kW | ||||

| Cycle time | 15-20s | ||||

| Rated pressure | 25Mpa | ||||

| Exciting force | 68kN | ||||

| Plate specification | 680×540×20mm | ||||

| Molding way | Vibration extrusion forming | ||||

| Stacker capacity | 3kW | ||||

| Block | Hollow block | Solid brick | Porous brick | Pavement brick | |

| Picture | |||||

| Size | 390×190×190 | 240×115×51 | 240×115×90 | 200×100×60/80 | 300×150×60 |

| Molding blocks | 3pcs/mold | 20pcs/mold | 12pcs/mold | 12pcs/mold | 6pcs/mold |

| Molding cycle | 15~20s | 20~30s | |||

| Per hour production | 540pcs/1h | 3600pcs/1h | 2160pcs/1h | 2160pcs/1h | 1080pcs/1h |

| Class production | 4320- 5760pcs/ 8h | 28800- 37400pcs/ 8h | 17280- 20160pcs/ 8h | 17280- 20000pcs/ 8h | 8640- 12600pcs/ 8h |

| Excitation frequency | 50~60Hz | ||||

| Block height | 50~200mm | ||||

| Power of main motor | 20kW | ||||

| Machine size | 5130×3850×2600mm | ||||

| Machine weight | 6200kg | ||||

**Note: The above parameters are for reference only. Modification and upgrades are available. Please contact us directly for more information.

The QT3-15 concrete block making machine is designed to meet the needs of small and medium sized companies for fully automatic block forming machines. If there are no special requirements needed on the production output, this cost-effective concrete block making machine is an ideal choice. This concrete block machine combines several advanced technologies, including intelligent PLC control, hydraulic transmission and vibration forming, making the machine's operation reliable, as well as carrying out a high production efficiency and excellent product quality.

To ensure the concrete block making machine works at its best in your factory or construction site, we will assign professional technical staff to provide on-site installation services. Our engineers can also help train your operators on operating, maintaining and correct use of the block making machine, in order to prolong its service life. If you have any questions or concerns about the fully automatic block making machine, please contact us directly.

Pictures of Details

360° gear

Material feeding system Vibrating table

Screws

For more molds and samples, please click ""

Links:https://www.globefindpro.com/products/70469.html

-

Rubber Expansion Joints

Rubber Expansion Joints

-

Dry Granulator (for Pharmaceutical and Food Industry)

Dry Granulator (for Pharmaceutical and Food Industry)

-

Vacuum Paddle Dryer (with Two Hollow Shafts)

Vacuum Paddle Dryer (with Two Hollow Shafts)

-

Fire Protection Butterfly Valve

Fire Protection Butterfly Valve

-

Post Indicator

Post Indicator

-

Flanged Ball Valve

Flanged Ball Valve

-

Welded Ball Valve

Welded Ball Valve

-

Gate Valve

Gate Valve

-

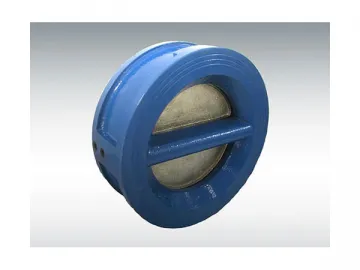

Wafer Check Valve

Wafer Check Valve

-

High Performance Butterfly Valve

High Performance Butterfly Valve

-

MW91b Cuffed Tracheostomy Tube

MW91b Cuffed Tracheostomy Tube

-

MW83b Silicone Foley Catheter

MW83b Silicone Foley Catheter