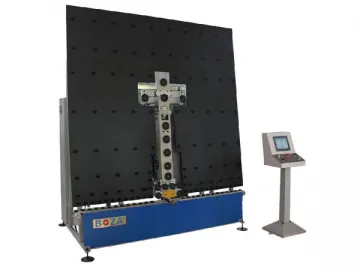

Butyl Extruder

As a professional automation machine supplier, we have provided customers butyl extruders, a specialized coating equipment for coating molten butyl sealants onto both sides of an aluminum spacer frame. With a scientific design, the automatic butyl coating machine is easy to operate, features a stable performance, high efficiency, and consistent, accurate butyl applications.

Technical Data

1. Power: AC380 V

2. Air Pressure: 0.6 MPa

3. Processing Spacer Width: 6-24 mm.

4. Processing Speed: 4 gear speeds, with a maximum value of 28m/minute, with a variable frequency. (This butyl rubber extruder has an independent memory for parameters that change with the speed adjustment)

5. Butyl Volume: 2 blocks (14L)

Features

1. The butyl extruder is designed with an automatic centering and clamping structure.

2. As it utilizes a man-machine interface, it is user friendly and easy to operate.

3. The machine comes equipped with 2 heating systems, both of which are separately controlled.

4. The nozzle width can be adjusted using a hydraulic cylinder system, making the performance reliable.

5. It is easy to replace the butyl, and an automatic alarm will sound when butyl levels are low.

6. As it is highly automated, the operator only needs to hold the aluminum spacer bar, and all other operations can be completed automatically, as programmed.

Applications

Due to its highly automated design, and the above features, the butyl extruder machine has become an indispensable sealant spreading machine for insulated glass manufacturing industries.

Key Components of the Bytul Extruder

| Key Components | Type | Brand |

| Controller | S7-200 | SIEMENS |

| Hydraulic valve | / | Huade |

| Air driven gas booster | MO37 | MAXIMATOR, Germany |

| Butyl pushing hydro-cylinder | Double-rod hydraulic cylinder | KOMPASS |

| Nozzle adjustment hydro-cylinder | CHK GB32-15 | SMC |

| Temperature control meter | E5C Series | OMRON |

| Solenoid valve | / | Airtec |

| Cylinder | / | Airtec |

| Frequency converter | 3G3MZ-A4007 | OMRON |

| Sensor | E3T-SL23 TL-Q5MC1-Z | OMRON |

| Touch Screen | TK6070i | Weinview |

Links:https://www.globefindpro.com/products/70571.html

-

Automatic Glass Loading Machine

Automatic Glass Loading Machine

-

Manual Two Component Sealants Extruder (Extrusion Pumps for Insulating Glass Manufacturing)

Manual Two Component Sealants Extruder (Extrusion Pumps for Insulating Glass Manufacturing)

-

Bonnell Spring Mattress (Memory Foam as Comfort Layer)

Bonnell Spring Mattress (Memory Foam as Comfort Layer)

-

Automatic Desiccant Filling Machine

Automatic Desiccant Filling Machine

-

Memory Foam Mattress

Memory Foam Mattress

-

Bonnell Spring Mattress (Classic Collection)

Bonnell Spring Mattress (Classic Collection)

-

Aluminum Heat Sink

Aluminum Heat Sink

-

Fabric Bed

Fabric Bed

-

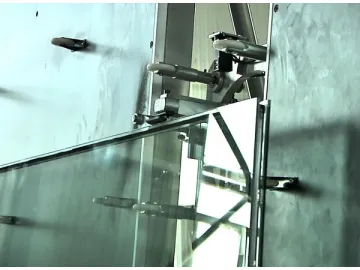

Automatic Vertical Edge Deleting Machine

Automatic Vertical Edge Deleting Machine

-

Pocket Spring Mattress (Natural latex as a Comfort Label)

Pocket Spring Mattress (Natural latex as a Comfort Label)

-

Automatic Sealing Robot

Automatic Sealing Robot

-

Headboards

Headboards