Crimping Machine

Crimping Machine The roofing roll forming machine makes roof panels. Then the crimping machines make roof panels curved.  Technical Data of the Crimping Machine

Technical Data of the Crimping Machine

The crimping machine is often used together with other metal forming equipment to assist in sheet metal forming and fabrication. It is especially popular for working with our roll forming machines to help fabrication of roofing sheets.

| Raw material | Corrugated steel sheet (235-345Mpa) |

| Material of roller | 45# steel being quenched |

| Material of crimping device | Cr12 mould steel with quenching treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Crimping speed | about 10times /minute |

| Power Requirement | Main motor power: 2.2Kw (Depend on final design) |

| Hydraulic station power | 5.5Kw (Depend on final design) |

| Diameter of shaft for rollers | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Quantity of feeding rollers | about 3 stations for main rollers |

| Weight of machine | About 3000KGS |

| Size of machine | about 1600mm×1600mm×1750mm |

Scan QR to Read

Links:https://www.globefindpro.com/products/70617.html

Links:https://www.globefindpro.com/products/70617.html

Recommended Products

-

Self Assembly Divan Bed Base

Self Assembly Divan Bed Base

-

Roll Forming Machine (For Steel Sigma Profiles)

Roll Forming Machine (For Steel Sigma Profiles)

-

UHF RFID Antenna

UHF RFID Antenna

-

Pre-painted Steel Coil

Pre-painted Steel Coil

-

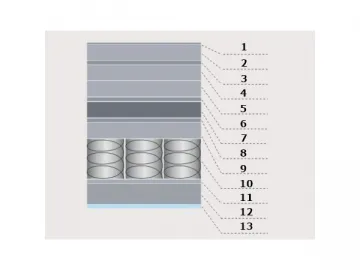

Bonnell Spring Mattress (Natural Latex as Comfort Layer)

Bonnell Spring Mattress (Natural Latex as Comfort Layer)

-

RFID Antenna

RFID Antenna

-

Mattress Sale Tools

Mattress Sale Tools

-

Wooden Divan Base

Wooden Divan Base

-

Pocket Spring Mattress

Pocket Spring Mattress

-

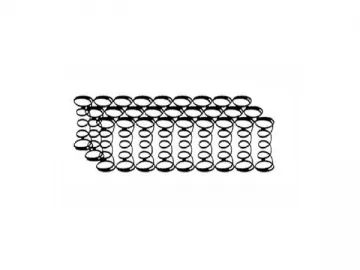

Continuous Coil Mattress (Classic Connection)

Continuous Coil Mattress (Classic Connection)

-

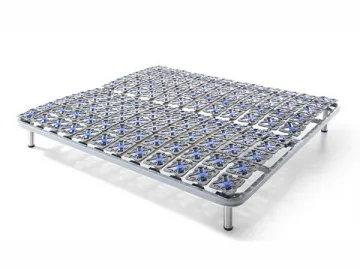

Wooden Slatted Bed Base

Wooden Slatted Bed Base

-

Bonnell Spring Mattress (As Children's Mattress)

Bonnell Spring Mattress (As Children's Mattress)