EPS Sandwich Panel Line

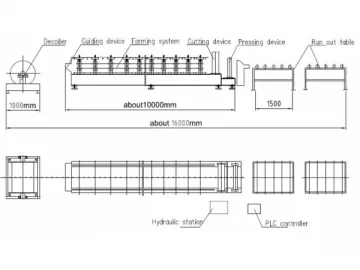

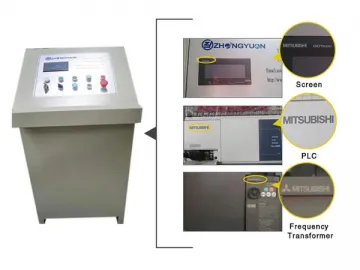

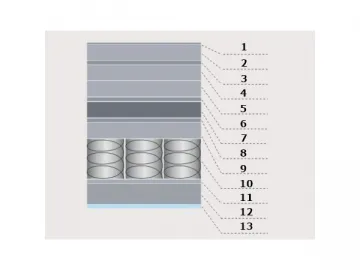

As its name indicates, the EPS sandwich panel line is designed to produce structural insulated panels with expanded polystyrene foam as the core. With PLC and touch screen control system, it is your perfect choice if you are looking for SIP production lines for the manufacturing of EPS insulated roof panel or wall panel.

| EPS Sandwich Panel Spec. | ||

| Panel thickness | Mini thickness | 50mm (wall panel) |

| Max. thickness | 200mm (exclude corrugated sandwich panel) | |

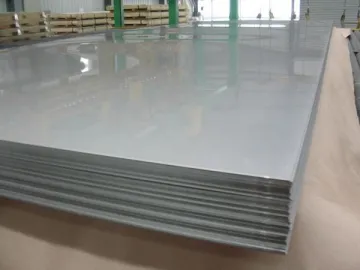

| Steel Sheet Spec. | ||

| Thickness | 0.4-0.7mm color steel sheet | |

| Width | 1250mm (we can design according to buyer's requirement) | |

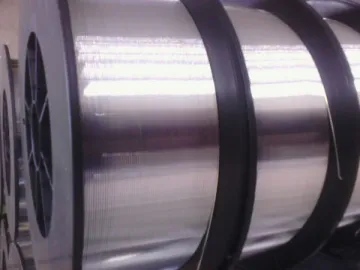

| Max. coil weight | 5 tons | |

| Inner Dia. of coil | 508mm | |

| Whole Production Line Spec. | ||

| Whole line dimension | about 35000mm × 2500mm × 3000mm | |

| Total weight | About 18t | |

| Working speed | About 5-7m/min (adjustable) | |

| The output | 1500m2-2000m2/8hour | |

| Control mode | PLC and converter | |

| Total power | About 28Kw (as per final designing) | |

| Power required | 380V/3phase/50Hz or as per customer's requirement. | |

| Air pressure | 0.7Mpa (for buyer to prepare) | |

| Suitable working temperature | About 25 degree | |

Consecutive laminating body makes EPS blocks stick to up and down sheets.

Machine can be designed according to customers’ requirements.

Applications of EPS Sandwich Panel Line

Due to its simple operation, this metal forming machinery is widely used to produce insulated wall and roof panels for steel structures, warehouses, workshops, cold storages, and mobile buildings.

In order to satisfy client-side various requirements, we can design and manufacture the sandwich panel production line in different specifications, models and configurations.

EPS Sandwich Panel Application ExampleLinks:https://www.globefindpro.com/products/70630.html

-

Aluminum Wire

Aluminum Wire

-

Roll Forming Machine (For Metal Roof and Wall Sheets)

Roll Forming Machine (For Metal Roof and Wall Sheets)

-

Hot Rolled Sheet

Hot Rolled Sheet

-

Roll Forming Machine (For Steel Cable Trays)

Roll Forming Machine (For Steel Cable Trays)

-

Roll Forming Machine (For Studs and Tracks)

Roll Forming Machine (For Studs and Tracks)

-

Embossing Machine

Embossing Machine

-

Roll Forming Machine (For Steel Roof Sheets)

Roll Forming Machine (For Steel Roof Sheets)

-

Aluminum Foil (for Household)

Aluminum Foil (for Household)

-

Welding Wire

Welding Wire

-

Roll Forming Machine (For Z Purlins)

Roll Forming Machine (For Z Purlins)

-

RFID Antenna

RFID Antenna

-

Bonnell Spring Mattress (Natural Latex as Comfort Layer)

Bonnell Spring Mattress (Natural Latex as Comfort Layer)