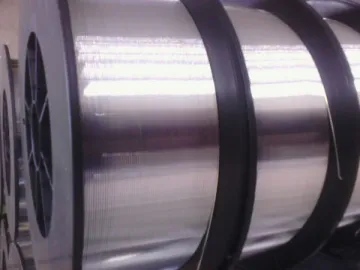

Hot Rolled Sheet

The industrial rolling of aluminum alloy sheets consists of 7 major operations: preliminary rolling of flat, continuously cast ingots with a weight of 0.5-5tons, straightening on roller straighteners, milling to obtain a pure and smooth surface, application of aluminum sheets to both sides of the ingot, heating, hot rolling with cladding to a thickness of 4-12mm with subsequent reeling, and finally, annealing and cold rolling. Our hot rolled sheets do not go through the cold rolling process.

Our 6-series hot rolled aluminum sheets, represented by aluminum alloy 6061 sheets, contains a larger amount of magnesium and silicone than other sheets. It features a high corrosion resistance and anti-oxidation features. As the alloy sheet has a high plasticity and excellent interfaces, as well as being easy to coat and process, it is primarily used in the production of low pressure weapons and plane adaptors. Customized aluminum sheets are also available upon request.

Technical Parameters of Hot Rolled Sheet| No. | Thickness(mm) | Width(mm) | Length(mm) | temper |

| 5005 | 0.2~6.0 | 200~2200 | 9500 | O H12 H14 H16 H18 H22 H24 H26 H32 H36 H111 H112 |

| 5052 | 0.3-80 | 1000-1500 | 1000~4000 | O H18/28 H14/24 H112 |

| 5083 | 0.2~8.0 | 1000~1500 | 1900~6000 | O H14 H34 H32 |

| specification | GB/T 3880 | |||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.50~1.1 | 0.10 | 0.25 | _ | spare |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | spare | |

| 5083 | 0.40 | 0.40 | 0.10 | 0.40~1.0 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | spare |

| Alloy | Tensile strength (MPa) | Elongation(%) | Annealing temperature℃ |

| 5005 | 100~205 | 1~8 | 345 |

| 5083 | 110~136 | ≥20 | 415 |

| Alloy No. | Thickness(mm) | Width(mm) | Length(mm) | Temper |

| 6061 | 1.2~20 | 100~800 | 2500(max) | O,F,T4,T5 |

| Standard | GB/T3880,GB/T3190,GB/T3199 | |||

Chemical Composition

| Alloy | Cu | Si | Fe | Mn | Mg | Zn | Cr | Ti | Al |

| 6061 | 0.15~0.4 | 0.4~0.8 | 0.7 | 0.15 | 0.8~1.2 | 0.25 | 0.04~0.35 | 0.15 | spare |

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 7075 | 0.40 | 0.50 | 1.2~2.0 | 0.3 | 2.1~2.9 | 0.18~0.28 | 5.1~6.1 | 0.2 | spare |

Links:https://www.globefindpro.com/products/70633.html

-

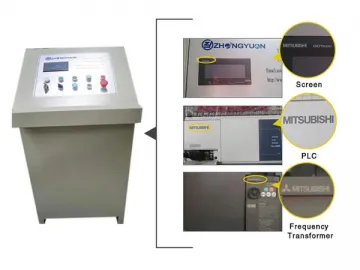

Roll Forming Machine (For Steel Cable Trays)

Roll Forming Machine (For Steel Cable Trays)

-

Roll Forming Machine (For Studs and Tracks)

Roll Forming Machine (For Studs and Tracks)

-

Embossing Machine

Embossing Machine

-

Roll Forming Machine (For Steel Shelf Panels)

Roll Forming Machine (For Steel Shelf Panels)

-

Roll Forming Machine (For Trapezoidal Sheets)

Roll Forming Machine (For Trapezoidal Sheets)

-

Pure Aluminum Wire

Pure Aluminum Wire

-

Roll Forming Machine (For Metal Roof and Wall Sheets)

Roll Forming Machine (For Metal Roof and Wall Sheets)

-

Aluminum Wire

Aluminum Wire

-

EPS Sandwich Panel Line

EPS Sandwich Panel Line

-

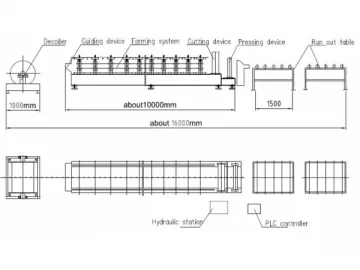

Roll Forming Machine (For Steel Roof Sheets)

Roll Forming Machine (For Steel Roof Sheets)

-

Aluminum Foil (for Household)

Aluminum Foil (for Household)

-

Welding Wire

Welding Wire