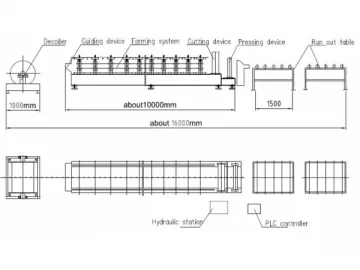

Roll Forming Machine (For Studs and Tracks)

Adopting cold rolled or galvanized steel strip with thickness between 0.5 and 0.6mm as the feeding material, the roll forming machine can be used to produce studs and tracks in an efficient way.

Technical Data of the Roll Forming Machine| Suitable Material | Cold-rolled steel strip and heat-treated galvanized steel strip |

| Thickness of raw material | 0.5-0.6mm (235-345Mpa) |

| Material of roller | 45# steel being quenched |

| Material of cutter blade& punching die | Cr12 mould steel with quenched treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Forming speed | about 20m/min |

| Power Requirement | Main motor power: 5.5 Kw(Depend on final design) |

| Hydraulic station power | 5.5Kw (Depend on final design) |

| Diameter of shaft for rollers | 55mm |

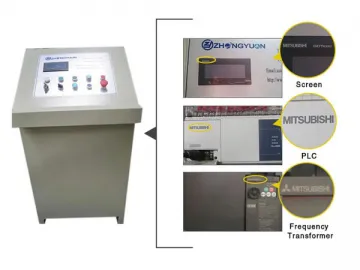

| Controlling system | Mitsubishi PLC & converter |

| Quantity of rollers | about 15 stations for main rollers |

| Weight of machine | About 6500KGS |

| Machine installation size | about 15m x 1.7 m x1.4m |

Advantages of the Roll Forming Machine

1. Anti-rust roller: The forming rollers for the sheet metal forming machine are CNC processed to improve precision, and come with 0.05mm thick chrome plating to enhance durability.

2. Heat treatment: To avoid deformation of the cutting frame, special heat treatment is performed to eliminate the steel stress.

3. Cutter blade: Made of Cr12 mould steel, the cutter blade for the roll forming machine also undergoes quenching treatment, which ensures extended lifespan.

4. High precision: The sheet metal fabrication equipment delivers very high precision, because of its CNC machined forming rollers and the roller shafts which are processed by grinding machine for at least twice.

5. User-friendly operation: The metalworking machinery is configured with Mitsubishi PLC control system with touch screen, which ensures easy operation and user-friendly man-machine interaction.

6. Excellent services: Upon request, we can send technicians to our clients' factories, so as to assist in machinery installation and operator training. All our roll forming machines are available with lifetime service.

Machine life of over 10 years.

Links:https://www.globefindpro.com/products/70635.html

-

Embossing Machine

Embossing Machine

-

Roll Forming Machine (For Steel Shelf Panels)

Roll Forming Machine (For Steel Shelf Panels)

-

Roll Forming Machine (For Trapezoidal Sheets)

Roll Forming Machine (For Trapezoidal Sheets)

-

Pure Aluminum Wire

Pure Aluminum Wire

-

Roll Forming Machine (For Corrugated Steel Sheets)

Roll Forming Machine (For Corrugated Steel Sheets)

-

Aluminum Trim Coil

Aluminum Trim Coil

-

Roll Forming Machine (For Steel Cable Trays)

Roll Forming Machine (For Steel Cable Trays)

-

Hot Rolled Sheet

Hot Rolled Sheet

-

Roll Forming Machine (For Metal Roof and Wall Sheets)

Roll Forming Machine (For Metal Roof and Wall Sheets)

-

Aluminum Wire

Aluminum Wire

-

EPS Sandwich Panel Line

EPS Sandwich Panel Line

-

Roll Forming Machine (For Steel Roof Sheets)

Roll Forming Machine (For Steel Roof Sheets)