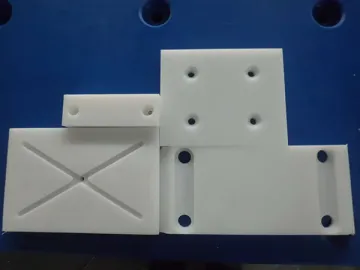

UHMWPE Dewatering Element

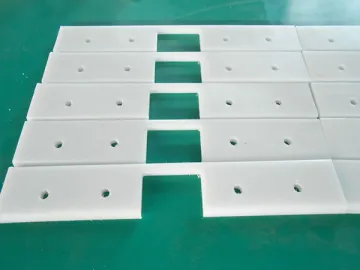

The UHMWPE dewatering element here is used as suction box cover for paper machinery. These UHMWPE machined parts have an extremely smooth surface with an exceptionally low friction coefficient, a low level of adhesion, and excellent chemical resistance.

For machines with speeds up to 800 m/min

Xinxing’s ultra-high molecular weight polyethylene UHMWPE dewatering elements set themselves apart with the special sintering press procedure used to manufacture them. This process for producing engineered plastic components ensures an outstanding service life for the plastic parts and creates a low coefficient of friction.

Advantages of UHMWPE Dewatering Elements

1. The measured coefficient of friction for the UHMWPE is 0.08 which is low compared to other plastics where the average friction is between 0.16 and 0.20, or cross grain wood (0.3).

2. UHMWPE dewatering elements allow for faster machine speeds thanks to a low coefficient of friction

3. This range of UHMWPE parts has high impact strength and will not break or splinter under normal operating conditions. Temperature resistant up to 1000℃.

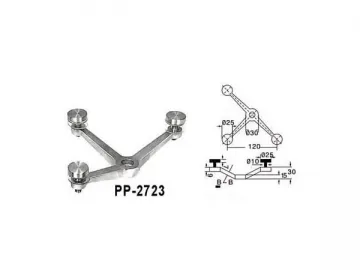

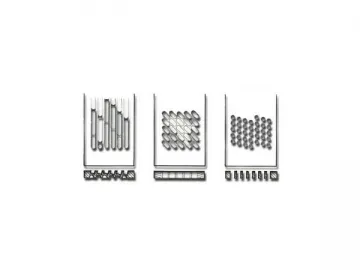

Perforation (three ways)

Size: suction box cover, made to your specifications.

Length is 1.2m, width is 1m, thickness is 60mm

Other sizes can be processed.

Color: White, yellow, blue, orange, green, and other custom colors.

Applications

Paper and pulp industry applications

At machine speeds of up to approx. 800 m/min

Technical Data of UHMWPE Dewatering Elements

| Properties | Unit | Method | |

| Density | g/cm3 | 527 / D 792 | 0.93-1 |

| Tensile strength at yield | MPa | 527 / D 638 | 17 |

| Tensile strength at break | MPa | 527 / D 638 | 40 |

| Elongation at break | % | 527 / D 638 | >50 |

| Modulus of elasticity in tension | MPa | 527 / D 638 | 650 |

| Modulus of elasticity in flexure | MPa | 178 / D 790 | 800 |

| Ball indentation hardness | MPa | 2039/1 | 35 |

| Impact Strength | kJ/m2 | 179 / D 256 | No br. |

| Creep rupture strength after 1000 hrs with static load | MPa | ||

| Time yield limit for 1% elongation after 1000 hrs | MPa | ||

| Coefficient of friction against hardened and ground steel p=0,05 N/mm2, v = 0,6 m/s | - | 0.29 | |

| Wear conditions as above | um/km | ||

| Crystalline melting point | ℃ | DIN 53 736 | plus 135 |

| Glass transition temperature | ℃ | DIN 53 736 | |

| Heat distortion temperature Method A Method B | ℃ ℃ | R 75 R 75 | 42 ~70 |

| Max. service temperature short term long term | ℃ ℃ | plus 120 plus 90 | |

| Coefficient of thermal conductivity | W/(m K) | 0.41 | |

| Specific Heat | J/(g K) | 1.84 | |

| Coefficient of thermal expansion | 10-5/K | DIN 53 483 / D 696 | 20 |

| Dielectric constant at 105 Hz | DIN 53 483 | 3 | |

| Dielectric loss factor at 105 Hz | DIN 53 483 | ||

| Specific volume resistance | Ω cm | DIN 60093 | 1014 |

| Surface resistance | Ω | DIN 60093 | 1012 |

| Dielectric strength 1mm | kV/mm | ASTM 149 | 45 |

| Tracking Resistance | 53 480 | KA3c, KB>600,KC>600 | |

| Moisture absorption: Equilibrium in standard atmosphere (plus23℃/ 50% relative humidity) | % | 62 | 0.01 |

| Water absorption at saturation at 23℃ | % | 62 | 0.01 |

| Resistance to hot water, washing soda | resistant | ||

| Flammability according to UL standard 94 | HB | ||

| Resistance to weathering | Natural: not resistant Black: resistant |

Links:https://www.globefindpro.com/products/71085.html