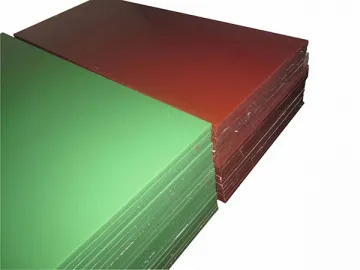

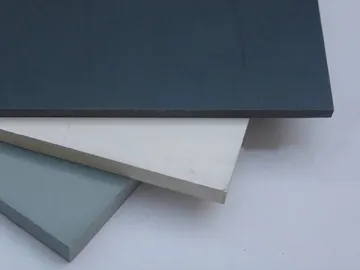

Rigid PVC Sheet

Xinxing produces rigid PVC sheets with a thickness of 1mm-30 mm. Custom PVC sheeting can also be made according to customer requirements.

Customizable Sizes of Rigid PVC Sheet

Thickness: 1mm-40mm

Width: 1mm-3mm:1m-1.3m

4mm-20mm:1m-1.5m

25mm-30mm:1m-1.3m

35mm-40mm:1m

Length: Any length

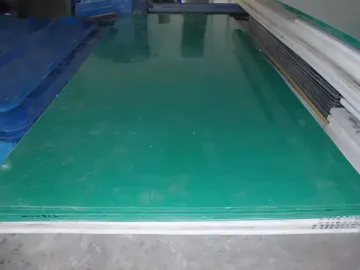

Surface: Glossy, matte, embossed

Standard colors: Dark grey ( RAL 7011), light grey, black, white, blue, green, red and any other colors available.

Characteristics of Rigid PVC Sheet

Excellent chemical and corrosion resistance

Outstanding impact strength

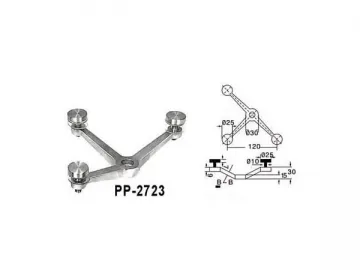

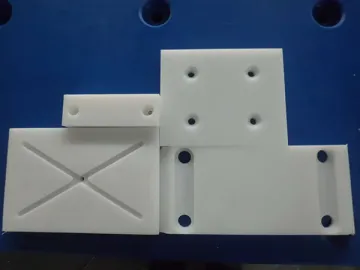

Easy to fabricate, weld, and machine

Vacuum formable

High rigidity and superior strength

Reliable electrical insulation

Low flammability

Self extinguishing

Applications

1) Our rigid PVC sheets are popular selections of industrial plastic sheets which are utilized in a number of industries for electrical, water, and chemical purposes.

2) PVC decoration sheets can be manufactured in various colors and styles for billboards and other advertising signboards.

3) UV stabilized PVC sheets are designed to be resistant to sunlight and to the weather. These properties make the plastic sheet the ideal choice for outdoor signage.

4) PVC vacuum forming sheets can be shaped into a variety of forms for decoration, the automotive industry, packaging, and other applications.

Classification

PVC Industrial Sheets

PVC Decoration Sheets

PVC UV Stabilized Sheets

PVC Vacuum Forming Sheets

Standard Sizes

| Thickness | 1220×2440mm | 1500×3000mm | 1300×2000mm | 1000×2000mm |

| 1mm-1.5mm | √ | √ | ||

| 2mm-3mm | √ | √ | √ | |

| 4mm-20mm | √ | √ | √ | √ |

| 25mm-30mm | √ | √ | √ | |

| 35mm-40mm | √ | |||

| We can also provide PVC rigid sheets of customized sizes | ||||

Technical Data of Rigid PVC Sheet

| Test Standard (GB/T 22789.1-2008) | Unit | Typical Value | |

| Physical | |||

| Density | 1.45-1.55 | g/cm3 | 1.45 |

| Mechanical | |||

| Tensile strength (length/breadth) | ≥45 | Mpa | 52.9/48.9 |

| Elongation(length/breadth) | ≥8 | % | 29/32 |

| Notch impact strength (Length/Breadth) | ≥5 | KJ/m2 | 7.83/7.57 |

| Charpy un-notched impact Strength 0℃-20℃ | --- | KJ/m2 | Pendulum 4J Sample not break |

| Bending strength V=2mm/min | --- | Mpa | 76.2 |

| Ball indentation hardness 358 N (H:0.118-0.138 ) | --- | N/m m2 | 221 |

| Thermal | |||

| Vicat softening temperature | ≧70 | ℃ | 76.8 |

| Heat shrinkage (Length/Breadth) | -4 to 4 | % | 1.9 / -0.1 |

| Deflection temperature under Load ( Length/Breadth) | ---- | ℃ | 69.5 /69.7 |

| Chemical | |||

| 35% /-1%(v/v)HCI 5h 60℃ | /-10 | g/cm3 | 5 |

| 30% /-1%(v/v)H2SO4 5h60℃ | /-8 | g/cm3 | 4 |

| 40% /-1%(v/v)HNO3 5h60℃ | /-8 | g/cm3 | 4 |

| 40% /-1%(v/v)Naoh 5h 60℃ | /-5 | g/cm3 | 2 |

| Electrical | |||

| Volume resistivity | --- | ohm.cm | 5.5×1013 |

Links:https://www.globefindpro.com/products/71094.html