Quilting and Embroidery Machine

As a professional industrial sewing machine supplier, we provide with customers this industrial embroidery machine---a type of computerized embroidery machine features simultaneous performance of quilting and embroidering. No matter you are a home textile maker, garment manufacturer, bags maker, shoes maker or other else, you can find the very embroidering machine you need here. Contact us to learn more.

Features

1. As its processing width is up to 3.2 m, this embroidery machine meets customer’s needs for patterns and processing width.

2. For garment industry, if the width requirement is less than 1.6 meters, this digital control embroidery machine can process two sheets of materials at the same time, significantly improving the output and efficiency.

3. Of high speed, high capacity and capacity to process thick materials, it boasts of flat and tidy quilting trace and has become choice equipment for quilting and embroidering process.

4. As it uses hook, independent needle bars and presser foot, the stitches are very smooth, clear and beautiful. Therefore, it is especially suitable for high-quality fabric quilting and embroidering.

5. Combining the functions of both quilting machines and embroidery machines, this textile equipment is capable to embroider floral patterns at once yet the quilting machine only can quilt and make some simple embroidery patterns;

6. Large hook which capacity of 120 meters of the bottom thread which can reduce the bobbins change over time and eliminate thread waste.

7. Of high speed, high capacity and capacity to process thick materials, it boasts of flat and tidy quilting trace and has become choice equipment for quilting and embroidering process.

Advanced Design

Three axes X,Y,Z are controlled by servomotors separately

Automatic detection of broken thread, with automatic suspension and back-process functions

Automatic memory of the current position in case of power cut-off.

The pattern-design system is acceptable to common embroidering machine; USB flash memory is used for storing patterns

The fabric pulling-up structure has three axes for adjustment

Effective clutch is matched well with the ROLLER structure at the front and the rear, to prevent any slipping of the fabric material

The needle rack is free of lubrication

The base thread can be used up, without waste

| Dimension | 5500mm X 1500mm X 1800mm |

| Gross weight | 4000kg |

| Processing width | 3200mm (128inch) |

| Processing thickness | ≤30mm |

| Moving rack range | 305mm (12inch ) |

| Shuttle speed | 100~800rpm(Adjustable) |

| Power source | 380V, 50Hz |

| Power | 6kW |

| Row of needle | single |

| Rotating hook quantity | 66pcs |

| Bottom thread length | 120m |

Links:https://www.globefindpro.com/products/71143.html

-

Synthetic Diamond Powder

Synthetic Diamond Powder

-

Mechanical Quilting Sewing Machine

Mechanical Quilting Sewing Machine

-

PVC Insulated Cable

PVC Insulated Cable

-

Bobbin Winder

Bobbin Winder

-

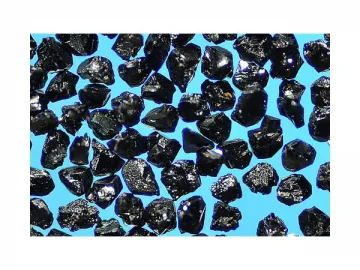

Cubic Boron Nitride (CBN Mono-crystal)

Cubic Boron Nitride (CBN Mono-crystal)

-

CBN Insert

CBN Insert

-

110 Inch Quilting Sewing Machine

110 Inch Quilting Sewing Machine

-

128 Inch Quilting Sewing Machine

128 Inch Quilting Sewing Machine

-

AAC / ACSR Conductor (All Aluminum Conductor/Aluminum Conductor Steel Reinforced)

AAC / ACSR Conductor (All Aluminum Conductor/Aluminum Conductor Steel Reinforced)

-

THHN / THWN Wire

THHN / THWN Wire

-

Digital Control Quilting Sewing Machine

Digital Control Quilting Sewing Machine

-

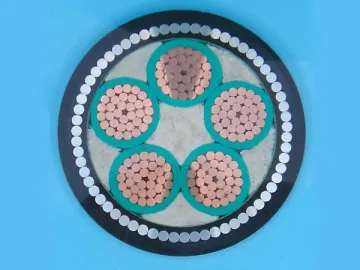

0.6/1kV PVC Insulated Power Cable

0.6/1kV PVC Insulated Power Cable