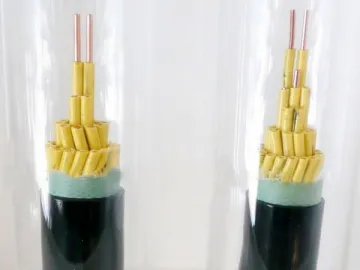

XLPE Insulated Power Cable (up to 35kV)

Leshan Cable Co. is a dedicated Chinese power cable manufacturer. Check out our wide range of electrical cables, which are available in various insulations, coatings, cable cores, and specifications.

The XLPE insulated power cable is used to transmit electricity on A.C.50Hz power transmission and distribution lines with rated voltage 35kV or lower. Compared to PVC insulated cable, the XLPE insulated electrical conductor boasts excellent electrical and mechanical properties, heat and aging resistance, environmental load resistance and chemical corrosion resistance. The simple and lightweight structure of the electrical cable allows for easy installation.

Standard Compliance for XLPE Insulated Power Cable

1. GB/T12706.1-2008(Reference standard: IEC60502-1) Rated Voltage 1kV(Um=1.2kV)and 3kV(Um=3.6kV)

2. GB/T12706.2-2008 (Reference standard: IEC60502-2) Rated Voltage 6kV(Um=7.2kV)to 30kV(Um=36kV)

3. GB/T12706.3-2008(Voltage grade exceeding IEC60502) Rated Voltage 35kV(Um=40.5kV)

Working conditions for XPLE Insulated Power Cable

1. Maximum working temperature of the insulated power conductor is 90℃

In case of a short (lasting less than 5 seconds) the maximum temperature of the cable conductor shall not exceed 250 ℃

Environment temperature should be no lower than 0℃ when laying the cable

2. Bending radius allowance of the XLPE insulated power cable

Single core cable: unarmored cable 20D; SWA cable 15D

Cores cable: unarmored cable 15D; SWA cable 12D

Notes: D = practical external diameter of cable.

| Type | Description | Applications | |

| Cu | Al | ||

| YJV | YJLV | XLPE insulation PVC sheath power cable | The cable can be used indoors, in tunnels, cable furrows and pipes. These cables cannot bear an outside mechanical force. |

| YJY | YJLY | XLPE insulation PE sheath power cable | |

| YJV22 | YJLV22 | XLPE insulation, steel tape armor, PVC sheath power cable | This particular cable can be used underground. It can bear a limited mechanical force, but is unable to bear large pulling forces. |

| YJV23 | YJLV23 | XLPE insulation, steel tape armor, PE sheath power cable | |

| YJV62 | YJLV62 | XLPE insulation, has none of the magnetism of steel tape armor, PE sheath power cable | |

| YJV32 | YJLV32 | XLPE insulation, thin steel-wire armor, PVC sheath power cable | These cables are applicable to wells (even with water inside), and can be placed in bad soil. The cables can bear an equal force outside the machine as it can inside. |

| YJV72 | YJLV72 | XLPE insulation, has none of the magnetism thick steel-wire armor does, PVC sheath power cable | |

| YJV42 | YJLV42 | XLPE insulation, thick steel-wire armor, PVC sheath power cable | These cables are applicable to the bottom of a well, and will function even underwater. Tjey can bear a larger pressure with a lead to support the force. |

| Hint specially | The single-core magnetism material that packs the cable is not applicable for use with AC power supply packs. The necessary hour limit uses a single-core 62 or 72 type power pack for the cable. | ||

| Rated cross area(mm2) | 0.5 | 0.75 | 1 | 1.5 | 2.5 | 4 | 6 | 10 | |

| Cu (Ω/km) | Non tinned | 36 | 24.5 | 18.1 | 12.1 | 7.41 | 4.61 | 3.08 | 1.83 |

| Tinned | 36.7 | 24.8 | 18.2 | 12.2 | 7.56 | 4.7 | 3.11 | 1.84 | |

| Al(Ω/km) | / | / | / | 18.1 | 12.1 | 7.41 | 4.61 | 3.08 | |

| Rated cross area(mm2) | 16 | 25 | 35 | 50 | 70 | 95 | 120 | 150 | |

| Cu (Ω/km) | Non tinned | 1.15 | 0.727 | 0.524 | 0.387 | 0.268 | 0.193 | 0.153 | 0.124 |

| Tinned | 1.16 | 0.734 | 0.529 | 0.391 | 0.27 | 0.195 | 0.154 | 0.126 | |

| Al(Ω/km) | 1.91 | 1.2 | 0.868 | 0.641 | 0.443 | 0.32 | 0.253 | 0.206 | |

| Rated cross area(mm2) | 185 | 240 | 300 | 400 | 500 | 630 | 800 | 1000 | |

| Cu (Ω/km) | Non tinned | 0.0991 | 0.0754 | 0.0601 | 0.047 | 0.0366 | 0.0283 | 0.0221 | 0.0176 |

| Tinned | 0.1 | 0.0762 | 0.0607 | 0.0475 | 0.0369 | 0.0286 | 0.0224 | 0.0177 | |

| Al(Ω/km) | 0.164 | 0.125 | 0.1 | 0.0778 | 0.0605 | 0.0469 | 0.0367 | 0.0291 | |

| Rated Voltage (kV) | 3.6/6 | 6/6 6/10 | 8.7/10 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

| Test Voltage(kV) | 6.23 | 10.38 | 15.05 | 20.76 | 31.14 | 36.33 | 44.98 |

| Discharge capacity(pC) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Rated Voltage(kV) | 0.6/1 | 1.8/3 | 3.6/6 3.6/10 | 6/6 6/10 | 8.7/10 8.7/15 | 12/20 | 18/30 | 21/35 | 26/35 |

| Test Voltage(kV) | 3.5 | 6.5 | 12.5 | 21 | 30.5 | 42 | 63 | 73.5 | 91 |

| Test Time(min) | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| U0/Um Area (mm2) | 0.6/1 | 3.6/6 | 6/6 6/10 | 8.7/10 8.7/15 | 12/20 | 18/20 18/30 | 21/35 | 26/35 | |

| Core No | 1 | 4-400 | 25-500 | 25-500 | 35-500 | 35-500 | 50-500 | 50-500 | 50-500 |

| 2 | 2.5-185 | / | / | / | / | / | / | / | |

| 3 | 2.5-300 | 25-300 | 25-300 | 35-300 | 35-300 | 50-300 | 50-300 | 50-300 | |

| 3 1 | 2.5-300 | / | / | / | / | / | / | / | |

| 4 | 2.5-300 | / | / | / | / | / | / | / | |

| 3 2 | 2.5-240 | / | / | / | / | / | / | / | |

| 4 1 | 2.5-300 | / | / | / | / | / | / | / | |

| 5 | 2.5-95 | / | / | / | / | / | / | / | |

Links:https://www.globefindpro.com/products/71159.html