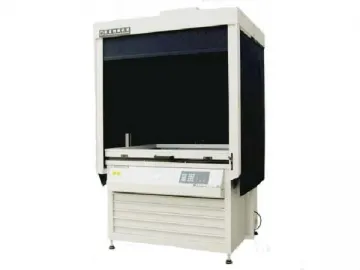

Two Color Offset Printing Machine (Large Format)

Features of Two Color Offset Printing Machine

1. Our two color offset printing machine has semi-automatic register set, which can facilitate fast and accurate register and reduce the auxiliary time.

2. This offset printing press can preset the paper thickness to help automatically, rapidly and simultaneously adjust the printing pressure when printing papers with different thicknesses.

3. Our two color offset printing machine has the non-stop paper feed unit, which can change the paper stack when the amount of papers has reached the requirement, reducing the time to stop the machine and change paper.

4. We adopt the mature CC-LINKtechnology of Mitsubishi to control the electric equipment of our offset press; it can achieve the contact among different units via the way of communication.

5. Consisting of the double-diameter impression rollers and double-diameter transfer rollers, the printing system of our two color offset printing machine is conducive to the printing of thick paper and cardboard; meanwhile, it can reduce the number of times of papers' transferring and generate accurate register.

6. Under centralized control, our offset printer's DC electric pulling plate controls the error of three directions: circumferential direction, axial direction and oblique direction. It can achieve convenient calibration of four-color plates and reduce the auxiliary time.

7. Our two color offset printing machine has five-roller structure, of which the intermediate rollers form an alcohol dampening system, which can help to effectively reducing the ghosting, quickly balance the ink and water, as well as save the paper consumption.

8. Composed of 20 partitions, the remote-controlled ink fountain can be adjusted via the touch screen on the main console. Our offset printing machine for sale can preset the ink and store files to be printed. In other words, it can easily access the printing materials and quickly move to the step of printing.

Parameters of Two Color Offset Printing Machine| Models | PRY-JD2660E | PRY-JD2740E |

| Maximum speed ( Pieces/ Hour) | 12,000 | |

| Maximum paper size | 540mm×660mm | 540mm×740mm |

| Minimum paper size | 273mm×393mm | |

| Printing paper thickness | 0.06mm-0.6mm | |

| Maximum printing area | 528mm×650mm | 528mm×730mm |

| Size of plate | 677mm×675mm×0.3mm | 677mm×755mm×0.3mm |

| Size of rubber blanket | 740mm×680mm | 740mm×760mm |

| Maximum height of paper feeding | 940mm | |

| Maximum height of paper collecting | 780mm | |

| Dimension | 5,400mm×2,880mm×1,870mm | |

| Total power | 13.2kw | |

| Net weight (approx.) | 10,700kg | 11,700kg |

Links:https://www.globefindpro.com/products/71255.html

-

Box Stitching Machine

Box Stitching Machine

-

Four Color Offset Printing Machine

Four Color Offset Printing Machine

-

Printing Down Frame

Printing Down Frame

-

Cardboard Box Making Machine

Cardboard Box Making Machine

-

Screen Printing Machine (3/4 Automatic)

Screen Printing Machine (3/4 Automatic)

-

Automatic Laminating Machine (SADF Series Double Side Type)

Automatic Laminating Machine (SADF Series Double Side Type)

-

Single Color Offset Printing Machine (Small Format)

Single Color Offset Printing Machine (Small Format)

-

Multifunctional Folder Gluer (For 4 and 6 Corner Cartons)

Multifunctional Folder Gluer (For 4 and 6 Corner Cartons)

-

Two Color Offset Printing Machine (Small Format)

Two Color Offset Printing Machine (Small Format)

-

UV Curing Machine

UV Curing Machine

-

Post-Press Equipment

Post-Press Equipment

-

Plate Punch

Plate Punch