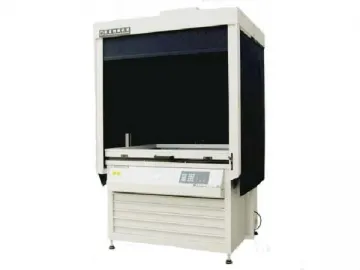

Small Format Flexo Printing Machine

Our narrow format flexo printing machine's maximum width of printing is 650mm, which is suitable for printing small paper. Its overall structure and components are consistent with the wide format flexo printing machine's.

Structures and Features of Narrow Format Flexo Printing Machine

1. Industry leading design and technology

2. The convenient drawer type design for quick installation and replacement

3. High-speed drying, infrared drying and hot air drying

4. Accurate horizontal and vertical register

5. Continuous control of printing materials and standard automatic correction

6. Manipulating console for easy operation

7. Clean and space-saving

| Narrow format series | 2000 | 3300 | 4200 | 4700 | 5200 | 6000 | 6500 |

| Maximum width of paper | 267mm | 340mm | 430mm | 480mm | 530mm | 610mm | 660mm |

| Maximum width of printing | 254mm | 330mm | 420mm | 470mm | 520mm | 600mm | 650mm |

| Maximum width of die cutting | 254mm | 330mm | 420mm | 470mm | 520mm | 600mm | 650mm |

| Width of repeat printing | 155mm- 508mm | 178mm- 508mm | 203.2mm- 635mm | 203.2mm- 635mm | 203.3mm- 2635mm | 241.3mm- 635mm | 241,1mm- 635mm |

| Width of repeat die cutting | 155mm- 508mm | 178mm- 508mm | 203.2mm- 635mm | 203,2mm- 635mm | 203.2mm- 635mm | 203.2mm- 635mm | 241.3mm- 635mm |

| Maximum diameter of winding | 1,016mm | 1,016mm | 1,016mm | 1,524mm | 1,524mm | 1,524mm | 1,524mm |

| Maximum diameter of unwinding | 610mm | 762mm | 1,016mm | 1,524mm | 1,524mm | 1,524mm | 1,524mm |

| Standard of gear | 1/8CP | 1/8CP | 1/8CP | 1/8CP | 1/8CP | 1/8CP | 1/8CP |

| Maximum mechanical speed | 152m/min | 152m/min | 152m/min | 152m/min | 152m/min | 152m/min | 152m/min |

| Power of main motor | 3kw-5.5kw | 5.5kw -7.5kw | 7.5kw -11kw | 11kw -13kw | 11kw -13kw | 11kw -15kw | 11kw -15kw |

| Lubrication system | Automatic | Automatic | Automatic | Automatic | Automatic | Automatic | Automatic |

| Air pressure | 0.6Mp | 0.6Mp | 0.6Mp | 0.6Mp | 0.6Mp | 0.6Mp | 0.6Mp |

| Power supply | 380V 50HZ | 380V 50HZ | 380V 50HZ | 380V 50HZ | 380V 50HZ | 380V 50HZ | 380V 50HZ |

Paper Feed Unit

The swing type hydraulic unit of our narrow format printer can hold the roll paper with the diameter up to 60 inches; and the air-expanding paper elements with the diameters of 3 inches, 6 inches, 12 inches are optional.

In order to ensure the reliable and stable operation of this flexographic printing press, we equip the paper feed unit with dust-extraction device, automatic correction and control device, pneumatic type artificial paper laying workbench, tension induction conversion device, magnetic powder brake or electro-pneumatic brake, tension controller, etc.

Printing Unit

Our narrow format flexo printing machine has two optional modes of register, the manual register and the electric register, which can both achieve high accuracy to meet the needs of high-quality printing.

Our narrow format flexo printing machine uniquely has enclosed ink supply system and self-cleaning function, helping you to clean the printing plate in the downtime.

We are pleased to configure the unit for backside printing and drawer type printing unit of anilox roller and roller for quick replacement according to your requirement.

Drying Unit

Our narrow format flexo printing machine has the installations of the infrared drying device and UV drying device, both of which can adjust the power. Also, the combination unit can be installed or separately used.

Strobe Monitoring System

Having the computer-based strobe monitoring system manufactured by the BST Company in USA, our narrow format flexo printing machine is convenient and practical for you to observe the printing color and the effect of register directly from the display.

Impression, Die Cutting, Waste Discharge and Paper Collection Unit

Our narrow format flexo printer for sale is capable of excellently accomplishing the following operation on the printing materials, such as impression, embossing, hot stamping, laminating, die cutting, etc.

In addition, this narrow format flexo printing machine can rewind the slitter edge discharge the printing waste via shredder. Besides, it can recycle the finished printing paper from the paper collection unit and winding workbench as well.

Control System

Inverter of Siemens and PLC intelligent control

Links:https://www.globefindpro.com/products/71263.html

-

RC Series Indoor Rental LED Display

RC Series Indoor Rental LED Display

-

M Series Stage Rental LED Display

M Series Stage Rental LED Display

-

PP Series LED Lightbox

PP Series LED Lightbox

-

FS Series Outdoor SMD LED Display

FS Series Outdoor SMD LED Display

-

FI Series Indoor Fixed LED Display

FI Series Indoor Fixed LED Display

-

Semi-Automatic Laminating Machine (KFMJ Series)

Semi-Automatic Laminating Machine (KFMJ Series)

-

Automatic Laminating Machine (SADF Series Double Side Type)

Automatic Laminating Machine (SADF Series Double Side Type)

-

Screen Printing Machine (3/4 Automatic)

Screen Printing Machine (3/4 Automatic)

-

Cardboard Box Making Machine

Cardboard Box Making Machine

-

Printing Down Frame

Printing Down Frame

-

Four Color Offset Printing Machine

Four Color Offset Printing Machine

-

Box Stitching Machine

Box Stitching Machine