410 Series Stranding Machine

If you are looking for an efficient and safe way to strand high carbon steel wires, Donghang’s 410 series of stranding machines is exactly what you need. This steel wire strander completes each stranding process using an automatic electric control box. In addition, the buncher is designed with a protective cover connected to an electric interlocking device that can start and stop the machine if needed, keeping the operator safe.

The wire bunching machine features a steel support structure and adopts imported seamless tubes as stranding drums so that the entire machine is durable and functions reliably. This stranding machine is perfect for processing brass plated high carbon steel wires, and thus is a very popular piece of wire machinery among steel wire and cable manufacturers.

Technical Parameters of the 410 Series of Stranding Machine

| Model | 410A6-9 | 410A-9 | |

| Work material | Brass plated high carbon steel wires | Brass plated high carbon steel wires | |

| Steel cord twisting structure | 3×0.20 6×0.35HT/SZ, 3 9×0.22/ss | 3 9, 3 8×0.33, 3 8×0.22, 2 7×0.22 | |

| Max. rotational speed | Core: 6000 rpm Face: 3000 rpm | Core: 6000 rpm Face: 3000 rpm | |

| Direction of twist | s/z, z/s | s/s, z/z | |

| Main machine | Pay-off spool | Diameter: φ188; Quantity: max. 4 | Diameter: φ188; Quantity: max. 4 |

| Motor | 11Kw-4P AC variable frequency motor | 11Kw-4P AC variable frequency motor | |

| Over twist motor | 0.75Kw Servo motor | 0.75Kw Servo motor | |

| Spindle and over twist shaft | SKF bearings | SKF bearings | |

| Take-up | Take-up motor | 1.1Kw-8P AC variable frequency motor | 1.1Kw-8P AC variable frequency motor |

| Take-up method | Pneumatic; B40, B60, B80, 607, 420 take-up spool | Pneumatic; B40, B60, B80, 607, 420 take-up spool | |

| ATC device | Standard flat spring: 1.2×0.33, 2.0×0.5 | Standard flat spring: 1.2×0.33, 2.0×0.5 | |

| Wire arrangement | Space between wires: 4±1.5mm; Motor: 120W reversible motor Clamped by synchronous belt | Space between wires: 4±1.5mm; Motor: 120W reversible motor Clamped by synchronous belt | |

Links:https://www.globefindpro.com/products/71338.html

-

Wet Wire Drawing Machine (21 Drawing Dies)

Wet Wire Drawing Machine (21 Drawing Dies)

-

SF Series Stranding Machine

SF Series Stranding Machine

-

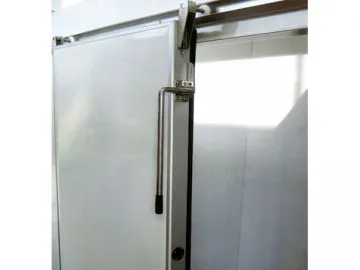

Cold Room Door (Sliding Door)

Cold Room Door (Sliding Door)

-

Double Twist Strander

Double Twist Strander

-

Tubular Stranding Machine

Tubular Stranding Machine

-

Cold Room / Cold Storage

Cold Room / Cold Storage

-

Audi LED Daytime Running Light

Audi LED Daytime Running Light

-

Rewinding Machine (5m/min)

Rewinding Machine (5m/min)

-

Coil Winding Machine

Coil Winding Machine

-

BMW LED Daytime Running Light

BMW LED Daytime Running Light

-

Wet Wire Drawing Machine (22 Drawing Dies)

Wet Wire Drawing Machine (22 Drawing Dies)

-

Take Up and Pay Off Stands (Max. 56 Steel Wires)

Take Up and Pay Off Stands (Max. 56 Steel Wires)