SF Series Stranding Machine

The SF series of stranding machines is available in multiple models, providing customers with more options in stranded wire structures and working efficiency. The steel wire stranding lines in this series is equipped with efficient sound insulating devices which effectively reduces noise. Additionally, this stranding machine uses a draught fan and exhaust fan in its main chamber, hence reducing the temperature so the cable manufacturing machinery is more durable.

Technical Parameters of the SF Series Stranding Machine

| Model | SF2 | SF4 | SF6 | SF9 | SF12/15 |

| Work material | Brass plated high carbon steel wires | Brass plated high carbon steel wires | Brass plated high carbon steel wires | Brass plated high carbon steel wires | Brass plated high carbon steel wires |

| Steel cord twisting structure | 2×0.3, 2 1×0.27, 2×1×0.27, 2 2×0.30 | 3×0.27, 4×0.25, 5×0.25, 3×7 | 3×0.175 6×0.32 | 2 7×0.22, 3 9×0.22, 7×4×0.175 | 3 8 13×0.22, 1 6 12×0.225 |

| Max. rotational speed | 6000Rpm | 6000Rpm | 4000Rpm | 4000Rpm | 3800Rpm |

| Direction of twist | S/Z | S/Z | S/Z | S/Z | S/Z |

| Pay-off spool | 2 spools, WS50 | 2 spools, WS50 and WS34 | 2 spools, WS50 and WS34 | 1 WS34 spoo1, 9 WS18 spools | φ420 spool and φ607 spool |

| Main motor | 11Kw-4P AC variable frequency motor | 11Kw-4P AC variable frequency motor | 15Kw-2P AC variable frequency motor | 15Kw-2P AC variable frequency motor | 15Kw-2P AC variable frequency motor |

| Over twist motor | 1.5Kw Servo motor | 1.5Kw Servo motor | 1.5Kw Servo motor | 1.5Kw Servo motor | 1.5Kw Servo motor |

| Take-up motor | 1.1Kw-8P AC variable frequency motor | 1.1Kw-8P AC variable frequency motor | 1.1Kw-8P AC variable frequency motor | 1.1Kw-8P AC variable frequency motor | 1.1Kw-8P AC variable frequency motor |

| Take up method | Pneumatic, quincuncial, top; B40, B60, B80, WS34 spools | Pneumatic, quincuncial, top; B40, B60, B80, WS34 spools WS18 | Pneumatic, quincuncial, top; B40, B60, B80, WS34 spools | Pneumatic, top; φ420 spool and φ607 spools | Pneumatic, top; B40, B60, B80, 607, 420 spools |

| Wire arrangement | 4± 1.5mm | 4± 1.5mm | 4± 1.5mm | 4± 1.5mm, | 4± 1.5mm |

Scan QR to Read

Links:https://www.globefindpro.com/products/71341.html

Links:https://www.globefindpro.com/products/71341.html

Recommended Products

-

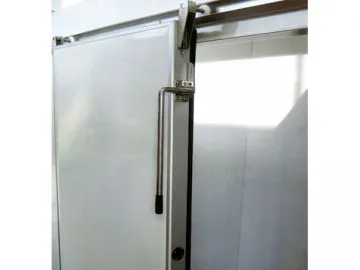

Cold Room Door (Sliding Door)

Cold Room Door (Sliding Door)

-

Double Twist Strander

Double Twist Strander

-

Tubular Stranding Machine

Tubular Stranding Machine

-

Cold Room / Cold Storage

Cold Room / Cold Storage

-

Take Up and Pay Off Stands (Max. 40 Steel Wires)

Take Up and Pay Off Stands (Max. 40 Steel Wires)

-

Galvanized Spool

Galvanized Spool

-

Wet Wire Drawing Machine (21 Drawing Dies)

Wet Wire Drawing Machine (21 Drawing Dies)

-

410 Series Stranding Machine

410 Series Stranding Machine

-

Audi LED Daytime Running Light

Audi LED Daytime Running Light

-

Rewinding Machine (5m/min)

Rewinding Machine (5m/min)

-

Coil Winding Machine

Coil Winding Machine

-

BMW LED Daytime Running Light

BMW LED Daytime Running Light

Hot Products