Tubular Stranding Machine

TU1 6

TU15

Our tubular stranding machine is specially designed for manufacturing steel cords and various stranded ropes. This wire strander comes in three models: the TU15 model, the TU300/18 model and the TU1 6 model.

Features of the Tubular Stranding Machine

1. Electrical components of this wire twisting machine are supplied by well-known and reliable brands such as a PLC and touch screen from Siemens, servo motor from Mitsubishi, etc., ensuring stable performance.

2. The wiring system for the tubular stranding machine is covered by quality flexible conduits that are protected by metallic tubes for double protection.

3. Filter screen in the draught fan won’t fall off and can be easily replaced if needed.

4. Our tubular strander is designed with wire fracture testing devices at the outlet and traction wheel, ensuring running safety.

5. A noise enclosure as well as an internal sound insulation and shock absorption layer significantly reduces noise.

6. A disk pneumatic brake provides the bunching machine with increased safety safety in operation.

Technical Parameters of the Tubular Stranding Machine

| Model | TU15 | TU1 6 | TU18-300 |

| Pay-off spool size | φ320 | φ253 | φ300 |

| Main motor power | 30Kw | 22Kw | 30Kw |

| Brake | Disk pneumatic brake | Disk pneumatic brake | Disk pneumatic brake |

| Max. rotating speed | 2200rpm | 1800 rpm | 1300rpm |

| Over-twist motor | 0.37Kw | 0.37Kw, with speed reducer brake motor | 1.5Kw |

| Take-up motor | 2.2Kw | 2.2Kw | 5.5Kw-6P AC variable frequency motor |

| Take-up spool | B40, B60, B80 | B40, B60, B80 | φ500 |

Links:https://www.globefindpro.com/products/71344.html

-

Cold Room / Cold Storage

Cold Room / Cold Storage

-

Take Up and Pay Off Stands (Max. 40 Steel Wires)

Take Up and Pay Off Stands (Max. 40 Steel Wires)

-

Galvanized Spool

Galvanized Spool

-

Edge Folded Spool

Edge Folded Spool

-

Spool

Spool

-

Welded Spool

Welded Spool

-

Double Twist Strander

Double Twist Strander

-

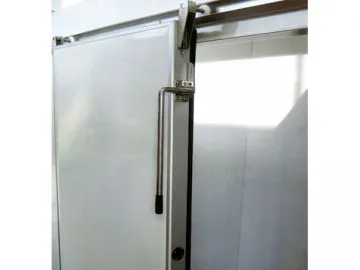

Cold Room Door (Sliding Door)

Cold Room Door (Sliding Door)

-

SF Series Stranding Machine

SF Series Stranding Machine

-

Wet Wire Drawing Machine (21 Drawing Dies)

Wet Wire Drawing Machine (21 Drawing Dies)

-

410 Series Stranding Machine

410 Series Stranding Machine

-

Audi LED Daytime Running Light

Audi LED Daytime Running Light