Take Up and Pay Off Stands (Dual Workstation)

If you are looking for a cable reel sized system for efficient wire spooling and de-spooling, then Donghang’s take up and pay off stands with a dual workstation is exactly what you need for your steel wire electroplating line. The wire spooling machine can reach a speed of DV76-120 and can process high carbon steel wires with a diameter range of 0.8-2.4mm.

This take-up and pay-off system uses a double-station passive vertical pay off method to achieve single wire control and integrated take-up. The quality welded steel structure with surface painting treatment lengthens the service life of the take up and pay off stand. As an expert in steel wire processing lines, Donghang also supplies corresponding spools according to your specific requirements. Buy all your supplies in one place with Donghang.

| Work material | High carbon steel wire |

| Wire diameter | φ2.4-0.8mm |

| Pay-off Stand | |

| Pay off type | Passive vertical pay off with dual workstation |

| Pay off spool size | φ1100×φ 508×750/642L |

| Take up Stand | |

| Take up type | Single wire control, integrated take up |

| Max. tension of driving wheel | 1800N |

| Max. winding capacity | 200N |

| Driving wheel diameter | φ350mm |

| Roller surface hardness | HRC60~62 |

| Traction wheel motor | Variable frequency motor, 2.2KW |

| Take-up motor | Variable frequency motor, 2.2KW |

| Tension control | Control torque |

| Take-up spool specifications | φ800×400×600/500L |

| Linear speed | DV76-120 |

Links:https://www.globefindpro.com/products/71355.html

-

TR Series Stranding Machine

TR Series Stranding Machine

-

Volkswagen LED Daytime Running Light

Volkswagen LED Daytime Running Light

-

Wire Straightener

Wire Straightener

-

Brass Plating Line for Steel Wire

Brass Plating Line for Steel Wire

-

Stamped Spool

Stamped Spool

-

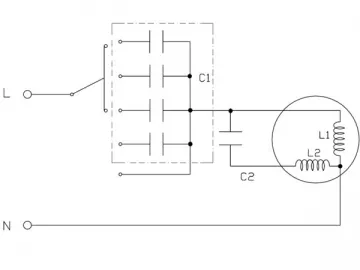

CBB61 Fan Capacitor (For Fan Regulators)

CBB61 Fan Capacitor (For Fan Regulators)

-

Wet Wire Drawing Machine (25 Drawing Dies)

Wet Wire Drawing Machine (25 Drawing Dies)

-

Rewinding Machine (10m/s)

Rewinding Machine (10m/s)

-

Wet Wire Drawing Machine (23 Drawing Dies)

Wet Wire Drawing Machine (23 Drawing Dies)

-

Welded Spool

Welded Spool

-

Spool

Spool

-

Edge Folded Spool

Edge Folded Spool