TR Series Stranding Machine

The TR series of stranding machines is comprised of a core wire pay-off unit, facial wire pay-off unit, wire guide stand, pre-twister, take-up unit and electric control cabinet. It is a double twist buncher that bunches high carbon steel wires with a diameter range of 0.17-0.23mm, and can make steel cords with various twisting structures. The dimensions of this double twist stranding machine are 8500 × 1400 × 3500mm and has a maximum speed of 3500rpm.

As one of our most popular styles of cable manufacturing equipment, the double twist bunching machine has earned us high reputations among steel wire rope and cable manufacturers.

Technical Parameters of the TR Series Stranding Machine

| Model | TR |

| Stranding material | Brass plated single wire, high carbon steel wire |

| Tensile strength | 280-320 kg/mm2 |

| Wire diameter | φ0.17mm / φ0.35mm |

| Steel cord structure | 3 9 15×0.17, 3 8 13×0.22 |

| Max. diameter of steel cord | φ1.38mm |

| Noise grade | Max. 85 db |

| Power supply | 380V 50Hz |

| Core wire pay-off unit | |

| Spool size | φ305 φ305 |

| No. of spool | 2 1 |

| Direction of twist | S/Z twist |

| Rotational speed | Max. 3500 rpm |

| Single wire pay-off unit | |

| Spool size | φ610×φ250×465 (610 spool) |

| No. of spool | 15 |

| Pay-off tension control device | 15 sets |

| Stranding take-up unit | |

| Applicable spools | B40, B60, B80, 305, 320 spools |

| Direction of twist | S/Z twist |

| Lay length | 16, 17, 18mm±0.5mm |

| Wire arranging method | Reciprocating screw rod |

| Space between wires | 6.4mm (B40, F75), 6.08mm(B80) |

| Wheel rotational speed | Max. 3500rpm |

| Motor power | 15Kw×4P |

| Fan power | 0.55Kw×2P(380V) |

Scan QR to Read

Links:https://www.globefindpro.com/products/71356.html

Links:https://www.globefindpro.com/products/71356.html

Recommended Products

-

Volkswagen LED Daytime Running Light

Volkswagen LED Daytime Running Light

-

Wire Straightener

Wire Straightener

-

Brass Plating Line for Steel Wire

Brass Plating Line for Steel Wire

-

Stamped Spool

Stamped Spool

-

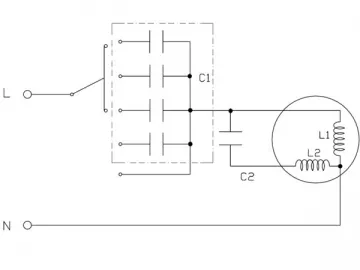

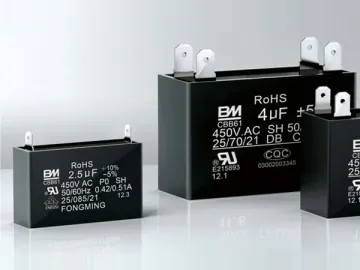

CBB61 Fan Capacitor (For Fan Regulators)

CBB61 Fan Capacitor (For Fan Regulators)

-

CBB61 Air Conditioner Capacitor (With Quick Connection Terminals)

CBB61 Air Conditioner Capacitor (With Quick Connection Terminals)

-

Take Up and Pay Off Stands (Dual Workstation)

Take Up and Pay Off Stands (Dual Workstation)

-

Wet Wire Drawing Machine (25 Drawing Dies)

Wet Wire Drawing Machine (25 Drawing Dies)

-

Rewinding Machine (10m/s)

Rewinding Machine (10m/s)

-

Wet Wire Drawing Machine (23 Drawing Dies)

Wet Wire Drawing Machine (23 Drawing Dies)

-

Welded Spool

Welded Spool

-

Spool

Spool

Hot Products