Wire Straightener

Our wire straightener is composed of a pay-off unit, straightening machine, take-up unit, and electric control cabinet and it processes brass plated steel cords. The wire straightening machine can be used for correcting some technological parameters of steel cords such as residual torsion, straightness, etc., and can serve as a wire rewinder as well.

The maximum take-up speed of this metalworking equipment is up to 150m/min. If customers want a wire straightener with a higher take-up speed, we can reconfigure it to better suit your needs.

Technical Parameters of Wire Straightener

| Work material | Brass plated steel cord |

| Max. take-up speed | 150m/min |

| Pay-off unit | Spool: B40,B60, B80 |

| Pneumatic clamping, passive pay-off | |

| Mechanical tension control, with balance wheel outlet device | |

| Motor | 2.2Kw-4P AC variable frequency motor |

| Over twist motor | 1.5Kw servo motor |

| Braking device | Disk pneumatic brake |

| Main frame | Welded frame with vibration aging treatment |

| Take-up motor | 1.1Kw-8P AC variable frequency motor |

| Take-up method | Pneumatic, quincuncial and top type B40, B60, B80, WS34 spools. |

| Wire arranging | Array pitch: 4±1.5mm Reversible motor: 120W Synchronous belt clamping |

Scan QR to Read

Links:https://www.globefindpro.com/products/71358.html

Links:https://www.globefindpro.com/products/71358.html

Recommended Products

-

Brass Plating Line for Steel Wire

Brass Plating Line for Steel Wire

-

Stamped Spool

Stamped Spool

-

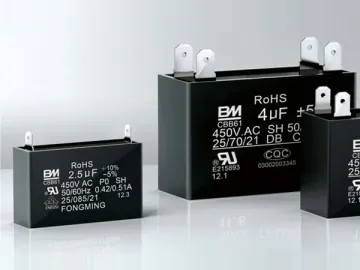

CBB61 Fan Capacitor (For Fan Regulators)

CBB61 Fan Capacitor (For Fan Regulators)

-

CBB61 Air Conditioner Capacitor (With Quick Connection Terminals)

CBB61 Air Conditioner Capacitor (With Quick Connection Terminals)

-

Cold Room Door

Cold Room Door

-

Cold Room Panel (Screw Fixed PU Panel)

Cold Room Panel (Screw Fixed PU Panel)

-

Volkswagen LED Daytime Running Light

Volkswagen LED Daytime Running Light

-

TR Series Stranding Machine

TR Series Stranding Machine

-

Take Up and Pay Off Stands (Dual Workstation)

Take Up and Pay Off Stands (Dual Workstation)

-

Wet Wire Drawing Machine (25 Drawing Dies)

Wet Wire Drawing Machine (25 Drawing Dies)

-

Rewinding Machine (10m/s)

Rewinding Machine (10m/s)

-

Wet Wire Drawing Machine (23 Drawing Dies)

Wet Wire Drawing Machine (23 Drawing Dies)

Hot Products