Brass Plating Line for Steel Wire

Donghang’s brass plating line for steel wires is ideal for making high carbon steel wires with 0.95% carbon content and a diameter range of 0.7-2.10mm. This plating machine achieves a total capacity of 12,800 tons per year. We provide a complete set of brass plating solutions by guiding you through your purchase and providing training for the brass plating line for high carbon steel wire so you can get the most out of your equipment.

Advantages of Donghang's Brass Plating Line

1. State-of-the-art technology: With efficient production and quality finished products, our brass plating system sets world leading standards.

2. This electroplating line for steel wire, designed and manufactured according to customer specifications, improves and expands production capacity.

3. With years of experience manufacturing steel wire copper plating lines, we offer our electroplating equipment at affordable costs, reducing your cost of investment.

Process Flow of Brass Plating Line

Pay-off → Surface adjustment → Open fire heating → Hot water washing → Water cooling → Alkali washing → Acid pickling→ Water washing → Brass plating → Water washing → Zinc plating → Water washing → Hot water washing → Ultrasonic spreading → Water cooling → Phosphoric acid pickling → Water washing → Soaping → Take-up

Why Choose Donghang?

1. Because of Donghang's rich experience in designing and manufacturing brass plated steel wire production lines, our talented R&D team has obtained 28 national patents.

2. We are IS09001:2000 and ISO9001:2004 certified.

3. Donghang offers customers turnkey projects with process and quality control, and provides technology improvement services for businesses looking to upgrade.

4. We can custom design and make various brass plating lines for high pressure hose steel wires or steel cord products according to customer specifications.

| Circulation cooling water | 30m3/h ≤ 31℃ |

| Pure water | 2Bar, 600L/h |

| Softened water | 2Bar, 500L/h |

| Tap water | 500L /h |

| Steam | 6Bar, 700Kg/h |

| Compressed air | 6Bar, 0.6m3/min |

| Electricity | 3×380 ± 10%VAC.650A |

| Natural gas | 50m3 |

Technical Parameters of Donghang's Brass Plating Line

| Work materials | High carbon steel wire, with 0.95% carbon content |

| Steel wire diameter range | 0.7-2.10mm |

| Average diameter | 1.40mm |

| Tensile strength | Max. 1850N/mm2 |

| Wire travel height in front of heating furnace | 915mm |

| Wire travel height from quenching to take-up | 935 - 965mm |

| Pay-off and take up height | 2100mm |

| Max. Speed (DV76) | 75m/min |

| Wire number | 48 wires |

| Copper content | 67%±1.0% |

| Plating layer weight | 5.5g/kg±0.5g/kg |

| Annual production capacity (Average diameter: 1.35; Time: 7,200 hours/year) | 12,800 tons per year |

Links:https://www.globefindpro.com/products/71359.html

-

Stamped Spool

Stamped Spool

-

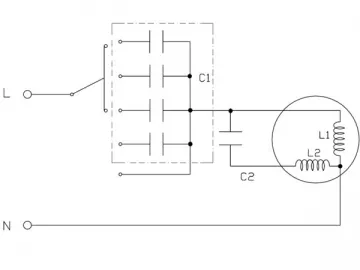

CBB61 Fan Capacitor (For Fan Regulators)

CBB61 Fan Capacitor (For Fan Regulators)

-

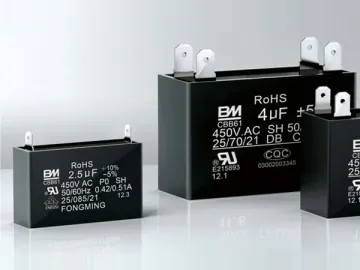

CBB61 Air Conditioner Capacitor (With Quick Connection Terminals)

CBB61 Air Conditioner Capacitor (With Quick Connection Terminals)

-

Cold Room Door

Cold Room Door

-

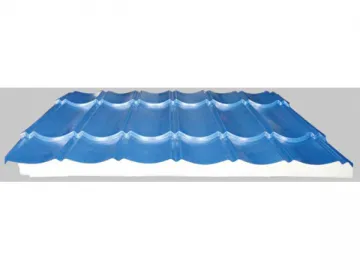

Cold Room Panel (Screw Fixed PU Panel)

Cold Room Panel (Screw Fixed PU Panel)

-

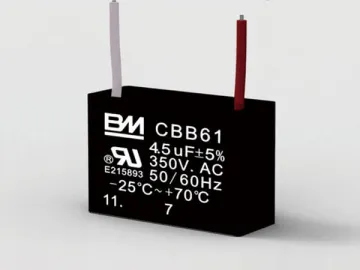

CBB61 AC Capacitor (With Two Wire Leads)

CBB61 AC Capacitor (With Two Wire Leads)

-

Wire Straightener

Wire Straightener

-

Volkswagen LED Daytime Running Light

Volkswagen LED Daytime Running Light

-

TR Series Stranding Machine

TR Series Stranding Machine

-

Take Up and Pay Off Stands (Dual Workstation)

Take Up and Pay Off Stands (Dual Workstation)

-

Wet Wire Drawing Machine (25 Drawing Dies)

Wet Wire Drawing Machine (25 Drawing Dies)

-

Rewinding Machine (10m/s)

Rewinding Machine (10m/s)