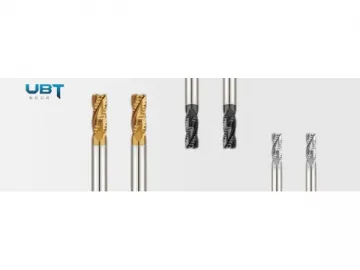

Drill Bits

Our hard alloy drill bits can create through holes or blind holes on work pieces and also enlarge holes. We can also provide customized drill bits, combined with other tools so customers can drill, mill, and ream.

Classification

Our hard alloy drill bits come in the following models. We also provide customized drill bits to fit your specific needs.

1. Twist Drill Bit

Twist drill bits with replaceable carbide blades or crowns are used to process cast iron, quenched steel and non-metallic materials, while integral solid carbide twist drill bits can process PCBs and parts of instruments.

2. Spade Bit

Spade bits, or flat drill bits, are the cheapest bits which easily allow coolants to enter, but their cutting performance and chip removal is not as strong as other bits. This drill bit comes as an integral drill bit, which is used to drill holes with a diameter from .03mm to .5mm, or a split drill bit which has replaceable blades and an internal cooling method and is meant for larger holes of 25-500mm in diameter.

3. Deep Hole Drill

Deep hole drills are drill bits with a processing depth-to-diameter ratio of over 6:1, and it includes gun drill bits, BTA drill bits,DF drill bits, and ejector drill bits. Core drills (also known as annular cutters) are also used for deep drilling.

4. Hole Enlarging Drill Bit

The hole enlarging drill bit is used to enlarge existing holes and improve hole precision and smoothness. It has 3 to 4 cutting edges, and has better rigidity than twist drills.

5. Countersink Drill Bit

A countersink drill bit uses several cutting edges to process the end face of a hole into a desired shape (such as a countersink), thus allowing the head of a countersunk screw to sit flush with the surface of the material. It may also be used to remove burrs for a smooth end face.

6. Center Drill Bit

Center drill bits are designed to provide a starting hole for a larger drill bit or to make a conical indentation in the end of a work piece in which to mount a lathe center. It is actually a combination of a twist drill bit and a countersink bit.

| Cutter diameter (mm) | Shank diameter (mm) | Cutting length (mm) | Total length (mm) |

| 2 | 2 | 12 | 38 |

| 2.5 | 2.5 | 14 | 43 |

| 3 | 3 | 16 | 46 |

| 3.5 | 3.5 | 20 | 52 |

| 4 | 4 | 22 | 55 |

| 4.5 | 4.5 | 24 | 58 |

| 5 | 5 | 26 | 62 |

| 5.5 | 5.5 | 28 | 66 |

| 6 | 6 | 28 | 66 |

| 6.5 | 6.5 | 31 | 70 |

| 7 | 7 | 34 | 74 |

| 7.5 | 7.5 | 34 | 74 |

| 8 | 8 | 37 | 79 |

| 8.5 | 8.5 | 37 | 79 |

| 9 | 9 | 40 | 84 |

| 9.5 | 9.5 | 40 | 84 |

| 10 | 10 | 43 | 89 |

| 10.5 | 10.5 | 43 | 89 |

| 11 | 11 | 47 | 95 |

| 11.5 | 11.5 | 47 | 95 |

| 12 | 12 | 51 | 102 |

| 12.5 | 12.5 | 51 | 102 |

| 13 | 13 | 51 | 102 |

| 13.5 | 13.5 | 54 | 107 |

| 14 | 14 | 54 | 107 |

| 14.5 | 14.5 | 56 | 111 |

| 15 | 15 | 56 | 111 |

| 15.5 | 15.5 | 58 | 115 |

| 16 | 16 | 58 | 115 |

| 16.5 | 16.5 | 60 | 119 |

| 17 | 17 | 60 | 119 |

| 17.5 | 17.5 | 62 | 123 |

| 18 | 18 | 62 | 123 |

| 18.5 | 18.5 | 64 | 127 |

| 19 | 19 | 64 | 127 |

| 19.5 | 19.5 | 66 | 131 |

| 20 | 20 | 66 | 131 |

| Serial Number: DIN6539 | |||

| Cutter diameter (mm) | Shank diameter (mm) | Cutting length (mm) | Total length (mm) |

| 3 | 3 | 6 | 50 |

| 4 | 4 | 8 | 50 |

| 5 | 5 | 10 | 50 |

| 6 | 6 | 13 | 50 |

| 8 | 8 | 16 | 60 |

| 10 | 10 | 20 | 75 |

| 12 | 12 | 25 | 75 |

| 16 | 16 | 30 | 100 |

| 20 | 20 | 30 | 100 |

| Note: Custom solid carbide spot drill bits are provided upon request. | |||

| Cutter diameter (mm) | Shank diameter (mm) | Cutting length (mm) | Total length (mm) |

| 3 | 3 | 10 | 50 |

| 4 | 4 | 12 | 52 |

| 5 | 5 | 15 | 60 |

| 6 | 6 | 20 | 66 |

| 8 | 8 | 25 | 79 |

| 10 | 10 | 25 | 89 |

| 12 | 12 | 30 | 102 |

| 16 | 16 | 35 | 115 |

| 20 | 20 | 40 | 131 |

| Note: Custom HSS spot drill bits are provided upon request. | |||

Links:https://www.globefindpro.com/products/71787.html