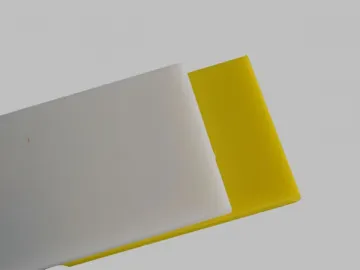

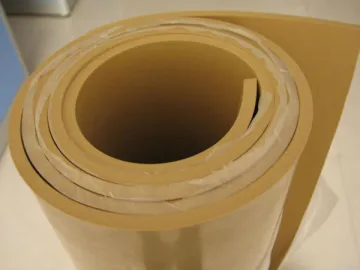

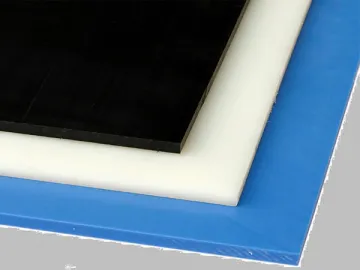

PTFE Sheet, PTFE Rod, PTFE Tube

Produced using new PTFE raw materials, our PTFE sheets, rods and tubes possess the following features

1. High temperature resistance: The long-term working temperature of our PTFE plastic tubes is 200~250℃.

2. Low temperature resistance: These PTFE plastic products remain soft under the temperature of -100℃.

3. Corrosion resistance: The PTFE sheets, rods and tubes are resistant to water and other organic solvents.

4. Won't Age with Weather: PTFE material features the longest service life among all plastic materials.

5. Smoothness: PTFE sheeting has a friction coefficient of 0.04, which is the lowest among all plastic materials.

6. No stickiness: The PTFE plastic sheet we offer comes with the lowest surface tension among solid materials and does not stick to other substances.

7. Outstanding electrical performance: Our PTFE sheets, rods and tubes have outstanding electrical performance and are C-class insulating materials. A piece of PTFE plastic sheet with the thickness of a newspaper is able to resist 1500V voltage.

Application

These PTFE sheets, rods and tubes are ideal for making sealing gaskets, ring materials, wear plates, insulating parts, mechanical parts, liners, etc. and they are widely used in the petroleum, natural gas and chemical industries.

Main Technical Parameters of PTFE Sheet, Rod & Tube

| Item | Unit | Index |

| Apparent density | g/cm3 | 2.10~2.30 |

| Tensile strength≥ | Mpa | 15.0 |

| Tensile strength≥ | % | 150 |

| Electrolysis intensity ≥ | kV/mm | 10 |

Regular Specifications of PTFE Sheet

| Length (mm)×Width (mm) | Thickness (mm) | |

| Nominal | Tolerance | |

| 150×150 | 1.0 ~ 150 | ±0.30 ~ ± 0.50 |

| 250×250 | 1.5 ~ 100 | ±0.30 ~ ± 0.50 |

| 300×300 | 1.5 ~ 100 | ±0.30 ~ ± 0.50 |

| 450×450 | 1.5 ~ 100 | ±0.30 ~ ± 0.50 |

| 600×600 | 1 ~ 100 | ±0.30 ~ ± 0.50 |

| 800×800 | 1 ~ 100 | ±0.30 ~ ± 0.50 |

| 1000×l000 | 1 ~ 100 | ±0.30 ~ ± 0.50 |

| 1200×1200 | 2 ~ 100 | ±0.30 ~ ± 0.50 |

| 1500×1500 | 3 ~ 100 | ±0.50 ~ ± 0.80 |

| 1600×1600 | 3 ~ 100 | ±0.50 ~ ± 0.80 |

| 2000×1000 | 3 ~ 100 | ±0.60 ~ ± 1 .0 |

| 1800×1800 | 3 ~ 100 | ±0.60 ~ ± 1 .0 |

| 2000×2000 | 3 ~ 100 | ±0.60 ~ ± 1 .0 |

Regular Specifications of PTFE Rod

| Outer diameter | Theoretical weight | Outer diameter | Theoretical weight |

| Φ5 | 0.0441 | Φ55 | 5.3429 |

| Φ6 | 0.0635 | Φ60 | 6.3585 |

| Φ7 | 0.0865 | Φ65 | 7.4624 |

| Φ8 | 0.113 | Φ70 | 8.6546 |

| Φ9 | 0.143 | Φ75 | 9.9351 |

| Φ10 | 0.1766 | Φ80 | 11.304 |

| Φ12 | 0.2543 | Φ 85 | 12.761 |

| Φ14 | 0.3641 | Φ 90 | 14.306 |

| Φ15 | 0.3974 | Φ95 | 15.94 |

| Φ16 | 0.4521 | Φ 100 | 17.662 |

| Φ18 | 0.5722 | Φ110 | 21.3716 |

| Φ20 | 0.7065 | Φ120 | 25.434 |

| Φ22 | 0.8548 | Φ130 | 29.849 |

| Φ25 | 1.1039 | Φ140 | 34.618 |

| Φ26 | 1.193 | Φ150 | 39.74 |

| Φ28 | 1.384 | Φ160 | 45.216 |

| Φ30 | 1.5896 | Φ170 | 51.044 |

| Φ35 | 2.1636 | Φ180 | 57.226 |

| Φ40 | 2.826 | Φ190 | 63.961 |

| Φ45 | 3.5766 | Φ200 | 70.65 |

| Φ50 | 4.4156 | Φ250 | 110.5 |

Regular Specifications of PTFE Tube

| Specification | Outer diameter (mm) | Wall thickness (mm) | Length ≥ (mm) | ||

| Nominal outer diameter | Tolerance | Nominal wall thickness | Tolerance | ||

| Pressed PTFE tubing | 0.5~4.0 | ±0.1~ ± 0.3 | 0.2~1.0 | ±0.06~ ± 0.3 | ≥4000 |

| 5.0~25.0 | ±0.5~ ± 1.0 | 1.0~25.0 | ±0.3~ ± 0.5 | ||

| Extruded PTFE tubing | 25~ 410 | ±0.5~ ± 3.0 | 22~ 400 | ±0.5~ ± 3.0 | ≤4200 |

| Molded PTFE tubing | 10~500 | ±0.5~ ± 5.0 | ≥7 | ±0.5~ ± 0.5 | ≤3 |

Links:https://www.globefindpro.com/products/72149.html