Blow Molding Machine (Rotary PET Stretch Blow Molding Machine)

Welcome to Longhong Machinery! We are a Chinese professional beverage machine manufacturer, providing customers with a wide range of blow molding machines. The CM-G series rotary PET stretch blow molding machines that we make come in 4-10 cavities and with a high rate of finished products that is up to 99.5%. They have become greatly popular PET blow molding machinery with high production capacity and efficiency.

The blow molding machine is equipped with FESTO solenoid valve and air cylinder, Siemens/Mitsubishi PLC and touch screen, and Schneider relay, ensuring high level of automation, stability, safety, high efficiency and other advantages. It can be used as cosmetic bottle blow molding machine, oil bottle blow molding machine, mineral water bottle blow molding machine, beverage bottle blow molding machine, etc. It is the preferred plastic bottle making machine for the industries of beverage, medicine, cosmetics, food and chemical.

Main Technical Parameters| Model | Item | CM-G4 | CM-G6 | CM-G8 | CM-G10 |

| Capacity | Depending on bottle design | 4,500-6,000pcs/h | 7,500-9,000pcs/h | 9,000-12,000pcs/h | 11,000-15,000pcs/h |

| Product type | Body diameter | ≤120mm | ≤120mm | ≤120mm | ≤120mm |

| Height | <325mm | <325mm | <325mm | <325mm | |

| Neck diameter | 18-38mm | 18-38mm | 18-38mm | 18-38mm | |

| Mould | Cavity number | 4 | 6 | 8 | 10 |

| Thickness | ø 190mm | ø 190mm | ø 190mm | ø 190mm | |

| Power | Power supply | 380V/220V, 50/60HZ, 3Phase | 380V/220V, 50/60HZ, 3Phase | 380V/220V, 50/60HZ, 3Phase | 380V/220V, 50/60HZ, 3Phase |

| Installed power | 120KW | 150KW | 180KW | 220KW | |

| Really use power | 50KW | 57KW | 80KW | 100KW | |

| Air source | HP air compressor | 6.4 m3/min, 3.0Mpa | 10.0 m3/min, 3.0Mpa | 12.0m3/min, 3.0Mpa | 16.0m3/min, 3.0Mpa |

| LP air compressor | - | - | 4.0m3/min, 1.0Mpa | 6.0m3/min, 1.0Mpa | |

| Air tank | 1.0 m 3, 3.0Mpa | 2.0 m3, 3.0Mpa | 2.0 m3, 3.0Mpa | 2.0 m3, 3.0Mpa | |

| Air dryer | 6.0m3/min, 3.0Mpa | 10.0m3/min, 3.0Mpa | 12.0m3/min, 3.0Mpa | 16.0m3/min, 3.0Mpa | |

| Cooling water | Water Chiller | 3HP | 5HP | 8HP | 10HP |

| Main machine size | Size (L×W×H) | 2780×4000×2100mm | 3200×2730×2190mm | 3600×3100×2190mm | 4200×3270×2190mm |

| Preform machine size | Size (L×W×H) | 1200×500×2800mm | 1200×500×2800mm | 1400×500×2800mm | 1800×800×2800mm |

| Hopper size | Size (L×W×H) | 1200×1100×750mm | 1300×1200×1000mm | 1500×1300×1200mm | 1600×1500×1200mm |

| Main machine weight | 4500 KG | 6000 KG | 8000 KG | 9000KG | |

| Raw material | PET | PET | PET | PET |

Features

1. This type of blow molding machine is energy saving. To be specific, the heating system adopts short chain unit (50.8mm). That is, same heating length can heat more preforms, thus saving 25% power.

2. High control precision, rapid response, Siemens electrical control system.

3. The plastic molding machine features stable performance. The air blowing system adopts German air valve and cylinder, enabling stable stretching speed and great product uniformity.

4. The blowing molding machine comes with a rapid mould installation mechanism which ensures reliable mould installation and quick replacement.

5. This plastic machinery employs automatic feeding device and recycling device, reducing labor cost.

Links:https://www.globefindpro.com/products/72171.html

-

EPDM Rubber Sheet

EPDM Rubber Sheet

-

Gravity Filling Machine

Gravity Filling Machine

-

Blow Molding Machine (100ml-750ml PET Bottle Making Machine, 1500-1800 Bottles per hour)

Blow Molding Machine (100ml-750ml PET Bottle Making Machine, 1500-1800 Bottles per hour)

-

Silicone Rubber Sheet

Silicone Rubber Sheet

-

NBR Rubber Sheet

NBR Rubber Sheet

-

Blow Molding Machine (100ml-2L PET Bottle Making Machine, 1400-1800 Bottles per hour)

Blow Molding Machine (100ml-2L PET Bottle Making Machine, 1400-1800 Bottles per hour)

-

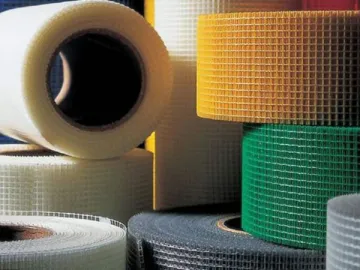

Fiberglass Mesh

Fiberglass Mesh

-

High Silica Fiberglass Fabric

High Silica Fiberglass Fabric

-

Blow Molding Machine (PET Bottle Machine for Producing 8000-10000 Plastic Bottles per hour)

Blow Molding Machine (PET Bottle Machine for Producing 8000-10000 Plastic Bottles per hour)

-

Anti Fatigue Floor Mat

Anti Fatigue Floor Mat

-

Water Treatment Equipment

Water Treatment Equipment

-

PP Sheet, PP Rod

PP Sheet, PP Rod