Blow Molding Machine (PET Bottle Machine for Producing 6000-7000 Plastic Bottles per hour)

In order to meet the requirements of food and beverage industry for various packaging bottles, LONGHONG, as the major beverage machinery manufacturer in China, offers not only whole set of beverage production lines and accessories but also a variety of PET bottles solutions. The CM-A6L blow molding machine shown here is an ideal solution for the plastic bottle makers who need large batch production.

The injection molding machine comes with six cavity moulds which enable a high production capacity of 6,000-7,000 bottles per hour. In addition to this, this blow molding machine boasts long lifetime, low noise and high safety.

Main Technical Parameters

| Model | CM-A6L | |

| Production Capacity | Depending on bottle design | 6,000-7,000pcs/h |

| Product type | Volume | ≤90mm |

| Body diameter | ≤325mm | |

| Height | 28mm-30mm | |

| Mould | Cavity number | 6 |

| Thickness | 240mm | |

| Power | Power supply | 380V/220V, 50/60HZ, 3Phase |

| Installed power | 56kw | |

| Really use power | 24kw | |

| Air source | LP air compressor | 2.0m3/min, 1.0MPa |

| HP air compressor | 3.2m3/min, 3.0MpaX2 | |

| Air dryer | 6.0m3/min, 3.0MPa | |

| Cooling water | Water Chiller | 5HP |

| Machine | Size (L×W×H) | 5000×2800×2200mm |

| Weight | 4800kg | |

| Preform unscrambler | Size (L×W×H) | 2300×1500×2480mm |

| Weight | 350kg | |

| Raw material | PET | |

Features

1. This PET blowing machine features simple structural design which is conductive to installation and maintenance.

2. Pneumatic and electrical components: International famous brands, such as Siemens, OMRON, etc.

3. The blow molding machine enjoys the functions of automatic alarming and automatic fault detection.

4. With an air conveying system, the PET bottle machine can be directly connected to filling machine.

Scan QR to Read

Links:https://www.globefindpro.com/products/72184.html

Links:https://www.globefindpro.com/products/72184.html

Recommended Products

-

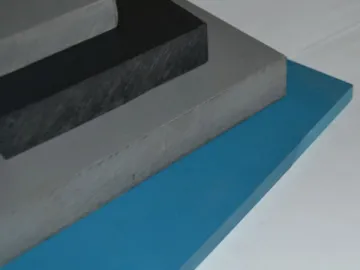

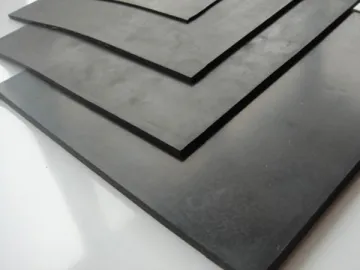

Rigid PVC Sheet

Rigid PVC Sheet

-

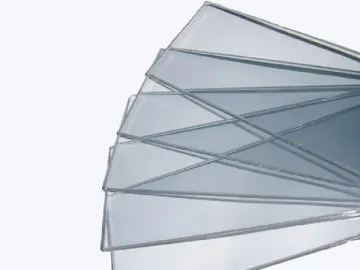

Transparent Rigid PVC Sheet

Transparent Rigid PVC Sheet

-

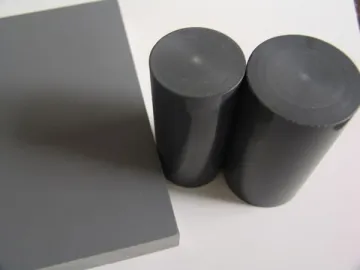

PVC Rod

PVC Rod

-

PU Sheet, PU Rod, PU Tube

PU Sheet, PU Rod, PU Tube

-

PVC Welding Rod

PVC Welding Rod

-

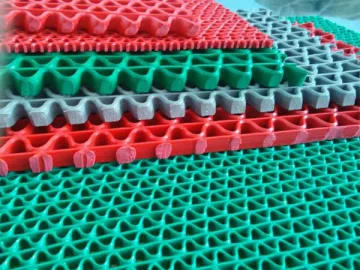

S Type PVC Floor Mat

S Type PVC Floor Mat

-

Hot Melt Labelling Machine

Hot Melt Labelling Machine

-

SBR Rubber Sheet

SBR Rubber Sheet

-

Blow Molding Machine (100ml-2L PET Bottle Making Machine, 600-900Bottles per hour)

Blow Molding Machine (100ml-2L PET Bottle Making Machine, 600-900Bottles per hour)

-

Liquid Filling Machine (Hot Fill Machine for Juice and Tea)

Liquid Filling Machine (Hot Fill Machine for Juice and Tea)

-

Antistatic Rubber Mat

Antistatic Rubber Mat

-

Blow Molding Machine (100ml-2L PET Bottle Making Machine, 1400-1800 Bottles per hour)

Blow Molding Machine (100ml-2L PET Bottle Making Machine, 1400-1800 Bottles per hour)