Blow Molding Machine (PET Bottle Machine for Manufacturing 1800-2000 Plastic Bottles per hour)

The CM-A2 blow molding machine is specially designed for manufacturing the PET bottles with capacity of less than 2L, height of 310mm and diameter of 100mm. This plastic bottle machine is equipped with two cavity moulds and can produce 1,800-2,000 bottles per hour. It perfectly serves as a kind of beverage machinery with reliable quality, high production efficiency and wide applications, and has won great recognition among the manufacturers of mineral water, sodas, juice, soya-bean milk, milk, wine and other drinks.

This type of blow molding machine is manufactured by LONGHONG that is a professional beverage machine manufacturer in China, providing you with a diversity of PET bottle machines including fully automatic blow molding machine, filling and packaging machines.

Main Technical Parameters

| Model | Items | CM-A2 |

| Capacity | Depend on bottle design | 1800-2000 PCS/H |

| Product type | Volume | ≤2L |

| Body diameter | ≤100mm | |

| Height | ≤310mm | |

| Neck diameter | ≤38mm | |

| Mould | Cavity | 2 |

| Thickness | 240mm | |

| Size | 260×240×370mm | |

| Main machine power | Electrical source power | 380V/220V, 50/60HZ, 3Phase |

| Installed power | 25kw | |

| Really use power | 6.5kw | |

| Air source | HP air compressor | 1.4 m3/min, 3.0Mpa |

| LP air compressor | 1.0 m3/min, 1.0Mpa | |

| Air Tank | 0.6m3, 3.0Mpa | |

| Air dryer | 1.0m3/min, 3.0Mpa | |

| Cooling water | Water Chiller | 3HP |

| Machine | Size (L×W×H) | 1900×1280×1930mm |

| Weight | 2000kg | |

| Preform unscrambler | Size(L×W×H) | 2000×950×2480mm |

| Weight | 250kg |

Features

1. This model of blow molding equipment comes with reasonable design and fully automatic control, which considerably reduce power consumption and labors.

2. It is designed with an infrared ray heating system for preheating the PET preforms. This effectively improves blow molding efficiency.

4. The blow molder features fully automatic production process with low investment, high efficiency, easy maintenance and operation, high safety, etc.

5. Due to the capability of storing technological parameters of different bottles in advance, the blow molding machine can directly taking data from the computer when changing moulds and preforms without having to adjusting it again.

Links:https://www.globefindpro.com/products/72193.html

-

Mini Electric Hoist (Hoist with Electric Beam Trolley)

Mini Electric Hoist (Hoist with Electric Beam Trolley)

-

Mini Electric Hoist

Mini Electric Hoist

-

Electric Chain Hoist

Electric Chain Hoist

-

Lever Hoist (Hand Operated Hoist)

Lever Hoist (Hand Operated Hoist)

-

Beam Trolley (Geared Trolley)

Beam Trolley (Geared Trolley)

-

Mini Electric Hoist (Hoist Mounted on a Bracket)

Mini Electric Hoist (Hoist Mounted on a Bracket)

-

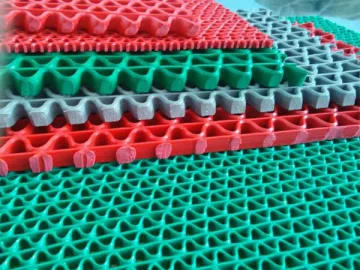

S Type PVC Floor Mat

S Type PVC Floor Mat

-

PVC Welding Rod

PVC Welding Rod

-

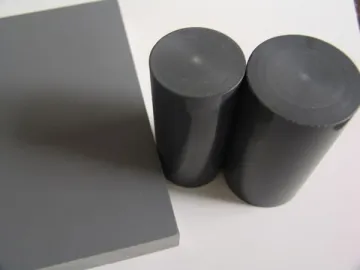

PU Sheet, PU Rod, PU Tube

PU Sheet, PU Rod, PU Tube

-

PVC Rod

PVC Rod

-

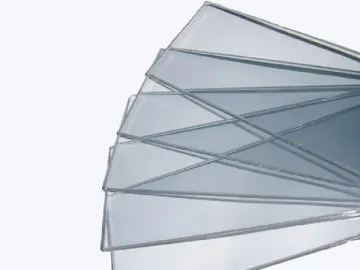

Transparent Rigid PVC Sheet

Transparent Rigid PVC Sheet

-

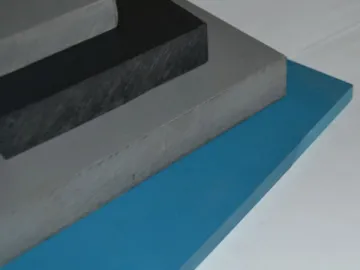

Rigid PVC Sheet

Rigid PVC Sheet