Blow Molding Machine (Plastic Bottle Machine for Manufacturing 5-10 Liter PET Bottles)

The CM9-9B semi-automatic blow molding machine is a perfect solution for 5-10L PET bottles, ensuring high and reliable performance. It can produce 250 to 400 bottles per hour and is widely used for making mineral water bottles, cosmetic bottles and oil bottles etc. This plastic bottle machinery is the first choice for liquid products manufacturers.

Main Technical Parameters

| Model | CM-9B | ||

| Bottle | Raw material | / | PET |

| Volume | L | 5-10 | |

| Theoretical output | pcs/h | 250-400 | |

| Height | mm | ≤390 | |

| Preform inner diameter | mm | φ15-200 | |

| Mould | Max. mould plate area (L×W) | mm | 470×500 |

| Max. thickness | mm | 370 | |

| Mould opening stroke | cm | 350 | |

| Machine size and weight | Outline dimensions (L×W×H) | mm | 1,930×720×1,830 |

| Main machine weight | kg | 800 | |

| Heater dimensions(L×W×H) | mm | 1,870×630×1,450 | |

| Heater weight | kg | 250 | |

| Rated power | kw | 17.5 | |

Features

1. The blow molding machine adopts double crank-shaft connecting rod mould clamping system which ensures firm mould clamping and rapid running speed. In addition, this cosmetic packaging machine is designed with a far infrared ray rotary heating oven which enables uniform heating.

2. The air circuit system is divided into moving and blowing parts for meeting the requirements for different air pressures. It can offer stable high pressure for blowing special large volume PET bottles.

3. This blow molding machine is equipped with a sound eliminator and oiling devices for each part, thus ensuring low noise and easy maintenance.

4. The PET bottle making machine comes in electric and semi-automatic modes.

Links:https://www.globefindpro.com/products/72207.html

-

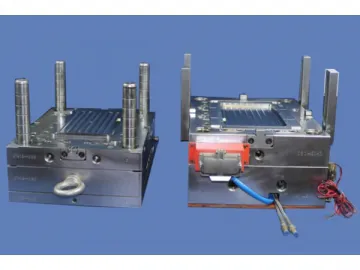

Blow Mould (Mould for Blowing Bottle Preform)

Blow Mould (Mould for Blowing Bottle Preform)

-

Magnetic Lifter (Permanent Lifting Magnet)

Magnetic Lifter (Permanent Lifting Magnet)

-

Blow Molding Machine (PET Bottle Machine for Manufacturing 3200-4000 Plastic Bottles per hour)

Blow Molding Machine (PET Bottle Machine for Manufacturing 3200-4000 Plastic Bottles per hour)

-

Hydraulic Pallet Truck

Hydraulic Pallet Truck

-

Plastic Injection Mould (Providing Mould for Making Home Appliance Parts)

Plastic Injection Mould (Providing Mould for Making Home Appliance Parts)

-

Liquid Filling Machine (This Machine for Filling Carbonated Drink)

Liquid Filling Machine (This Machine for Filling Carbonated Drink)

-

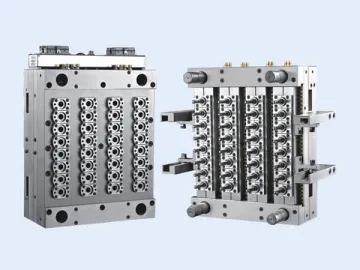

Preform Mould

Preform Mould

-

Blow Molding Machine (Plastic Bottle Machine for Making 2-5 Liter PET Bottles)

Blow Molding Machine (Plastic Bottle Machine for Making 2-5 Liter PET Bottles)

-

Electric Chain Hoist (PDH hoist with Electric Trolley)

Electric Chain Hoist (PDH hoist with Electric Trolley)

-

Plastic Injection Mould (Supplying Auto Parts Mould)

Plastic Injection Mould (Supplying Auto Parts Mould)

-

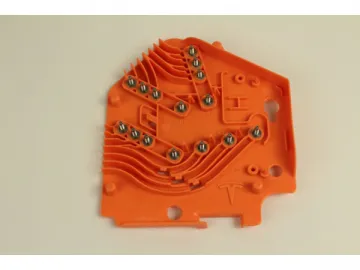

Plastic Injection Mould (Offering Electronic Products Mould)

Plastic Injection Mould (Offering Electronic Products Mould)

-

Mini Electric Hoist (Hoist Mounted on a Bracket)

Mini Electric Hoist (Hoist Mounted on a Bracket)