Blow Molding Machine (PET Bottle Machine for Making Maximum 1.5L or 5L Plastic Bottle)

This blow molding machine made by LONGHONG, the major PET blow molding machine manufacturer in China, is a fully automatic PET bottle machine for making maximum 1.5L or 5L plastic bottles with low cost, high production capacity and low waste rate as well as higher stability than semi automatic ones.

This PET bottle making machine is available in two models, i.e. CM-B2 and CM-C3. The CM-B2 blow molding machine is mainly used to make maximum 5L PET bottles in all shapes, with a capacity of 800-1000pcs/h. The CM-C3 model is great for making maximum 1.5L plastic bottles with a capacity of 1,800-2,500pcs/h.

These two types of blow molders can be wildly used for blowing mineral water bottles, daily bottles and cosmetics bottles, meeting the production requirements of most beverage factories, cosmetic factories, pesticide factories and bottle manufacturers.

Main Technical Parameters

| Model | ITEM | CM-B2 | CM-C3 |

| Productivity | Depend on bottle design | 800-1000PCS/H | 1800-2500PCS/H |

| Product type | Volume | ≤5L | ≤1.5L |

| Body diameter | ≤175mm | ≤100mm | |

| Height | ≤330mm | ≤305mm | |

| Neck diameter | 40mm-45mm | 28mm-30mm | |

| Mould | Cavity | 2 | 3 |

| Mold thickness | 260mm | 240mm | |

| Mold size | 480×260×380mm | 450×240×360mm | |

| Main machine power | Electrical source power | 380V/220V 50/60HZ 3Phase | 380V/220V 50/60HZ 3Phase |

| Power | 33kw | 25kw | |

| Really use power | 13kw | 9.5kw | |

| Air system | HP air compressor | 4.0m3/min, 3.0Mpa | 2.0m3/min, 3.0Mpa |

| LP air compressor | 1.6m3/min, 1.0Mpa | / | |

| Air Tank | 1.0m3, 3.0Mpa | 1.0m3, 3.0Mpa | |

| Air dryer | 4.0m3/min, 3.0Mpa | 2.0m3/min, 3.0Mpa | |

| Cooling water | Water Chiller | 3HP | 3HP |

| Machine | Size(L×W×H) | 2500×1500×1800mm | 2000×1300×1800mm |

| Weight | 2200kg | 1800kg | |

| Preform unscrambler | Size(L×W×H) | 2000×950×2480mm | 2000×950×2480mm |

| Weight | 250kg | 250kg |

Features

1. This blow molding machine conducts fully automatic production process, avoiding the danger from manual bottle picking, reducing loss caused by security incidents and improving production efficiency.

2. Such plastic machinery is equipped with far infrared ray oven and quartz burner for heating PET preforms, thus making them heated much more uniformly.

3. Driven by air cylinder instead of oil pump, this type of blow molding machine features easier maintenance and lower noise.

4. The processing machinery for plastic bottles features high level of automation, high pressure mould clamping system and easy operation.

Links:https://www.globefindpro.com/products/72218.html

-

Chain Block (Manual Chain Hoist)

Chain Block (Manual Chain Hoist)

-

Electric Chain Hoist (PDH Stage Hoist)

Electric Chain Hoist (PDH Stage Hoist)

-

Electric Chain Hoist (PDH Electric Chain Hoist with Hook)

Electric Chain Hoist (PDH Electric Chain Hoist with Hook)

-

Electric Chain Hoist (PDH Hoist with Manual Trolley)

Electric Chain Hoist (PDH Hoist with Manual Trolley)

-

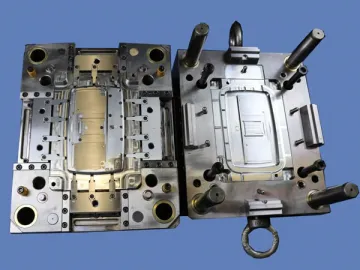

Plastic Injection Mould (Manufacturing Mould for Making Medical Equipment Parts)

Plastic Injection Mould (Manufacturing Mould for Making Medical Equipment Parts)

-

Electric Beam Trolley

Electric Beam Trolley

-

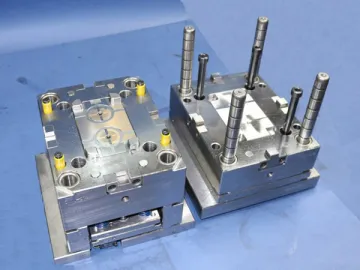

Plastic Injection Mould (Producing Mould for Office Equipment Parts)

Plastic Injection Mould (Producing Mould for Office Equipment Parts)

-

Beam Trolley (Hand Push Trolley)

Beam Trolley (Hand Push Trolley)

-

Blow Molding Machine (PET Bottle Machine for Making Maximum 2L or 5L Plastic Bottle)

Blow Molding Machine (PET Bottle Machine for Making Maximum 2L or 5L Plastic Bottle)

-

Liquid Filling Machine (This Machine for Filling Carbonated Drink)

Liquid Filling Machine (This Machine for Filling Carbonated Drink)

-

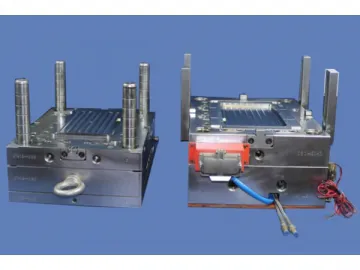

Plastic Injection Mould (Providing Mould for Making Home Appliance Parts)

Plastic Injection Mould (Providing Mould for Making Home Appliance Parts)

-

Hydraulic Pallet Truck

Hydraulic Pallet Truck