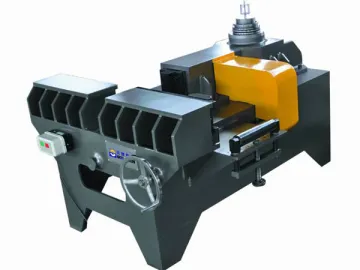

TAPM1412 CNC Angle Line (Including CNC Metal Marking, Punching, Shearing Machine)

Our TAPM1412 CNC metal punching, marking, shearing machine for angle steels can offer you effective and productive CNC machinery solutions for processing angle steel, square tubes and flat plates.

In the tower industry the operation usually faces a tight schedule and a harsh working environment with exposure to extreme climates. Our enhanced CNC facility features outstanding performances and provides powerful marking, punching and cutting for the tower industry. This equipment is also suitable for the electrical and telecommunications industries.

Features

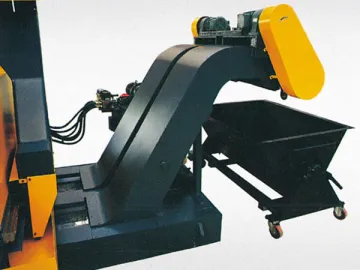

1.The marking, punching and cutting are all automatically controlled. Finished products are pneumatically rotated and unloaded, which significantly reduces the labor intensity.

2. This CNC angle line can function as a single blade machine, which saves material.

3. It can process material with a fixed length, avoiding shearing.

4. It supports both the Chinese and English language, making it easy to operate, and displays the work piece's figure

5. CNC technology has been applied to this automatic angle steel machining equipment. Its feeding system is controlled by a servo motor, making it highly efficient and generates work pieces with stable precision.

6. Programming is easy, and you can input the dimensions, bore diameters stadia and number of work pieces.

7. As it is equipped with a material salver device and material press device, this enhanced CNC punching equipment can adapt angle steel with bigger curvatures.

8. With its brand new closed frame, the marking unit has superb rigidity. The marking stadia can be set randomly.

9. This CNC machinery for angle steel's programming is simple and data generated from the sample software can be directly used.

10. The CNC angle line has a self-diagnostic function for finding faults.

11. The hydraulic parts, pneumatic components and electrical elements are all imported and stable quality.

Parameters of TAPM1412 CNC Processing Equipment| Model | TAPM1412 |

| Processing range(mm) | From 40×40×3 to 140×140×12 (Q420) |

| Max. length of workpiece (m) | 12 |

| Max. punching capacity (diameter × thickness) (mm) | Φ26х12 |

| Punching force (kn) | 1,000 |

| Marking force (kn) | 1,030 |

| Shearing force (kn) | 1,800 |

| Max. length of workblank (m) | 14 |

| Max. length of finished product (m) | 14 |

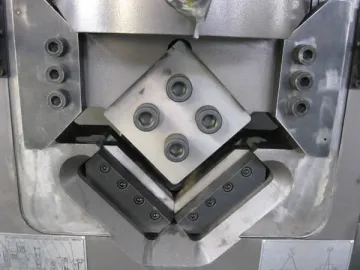

| Number of punching head on each side | 3 |

| Number of character marking group | 4 |

| Number of character in each marking group | 15 |

| Dimension of character (mm) | 14×10×19 |

| Adjustable range of stadia (mm) | From 20 to 170 (stepless) |

| Number of CNC axes | 3 |

| Cutting mode | Dual blades cutting |

| Max. feeding speed of angle steel (m/min) | 60 |

| Processing precision | In accordance with GB2694-81 |

| Programming mode | Keyboard input, RS232 interface, floppy disk and USB interface |

| Dimension (mm) | 26,000×7,000×3,000 |

| Weight (kg) | 16,500 |

Links:https://www.globefindpro.com/products/72292.html

-

TSWZ1000 / TSWZ1250 CNC Beam Drilling Line

TSWZ1000 / TSWZ1250 CNC Beam Drilling Line

-

TPLD2020 / TPLD2525 / TPLD3030 CNC Plate Drilling Machine

TPLD2020 / TPLD2525 / TPLD3030 CNC Plate Drilling Machine

-

Straightening Machine

Straightening Machine

-

TPPR103 / TPPR104 CNC Hydraulic Punching Machine

TPPR103 / TPPR104 CNC Hydraulic Punching Machine

-

TPD16 / TPD30 CNC Plate Drilling Machine

TPD16 / TPD30 CNC Plate Drilling Machine

-

TBL2532 CNC Angle Line (CNC Drilling and Metal Marking Machine)

TBL2532 CNC Angle Line (CNC Drilling and Metal Marking Machine)

-

TDJ1000 / 1250 CNC Band Saw Machine

TDJ1000 / 1250 CNC Band Saw Machine

-

CNC Press Brake

CNC Press Brake

-

TPP103 / TPP104 CNC Hydraulic Punching Machine

TPP103 / TPP104 CNC Hydraulic Punching Machine

-

Compatible BANKSTAR Printer Ribbon

Compatible BANKSTAR Printer Ribbon

-

Compatible EPSON Printer Ribbon

Compatible EPSON Printer Ribbon

-

Compatible C.ITOH Printer Ribbon

Compatible C.ITOH Printer Ribbon