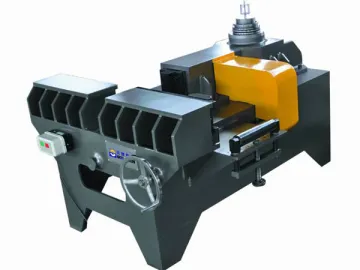

TPLD2020 / TPLD2525 / TPLD3030 CNC Plate Drilling Machine

Application

Our CNC plate drilling machine can be used for drilling holes on tube, baffle and flange plates in petrochemical, boiler, refrigeration and wind power industries. This CNC drilling machine can also drill the junction plates for steel structures in construction, bridge and tower industries.

Features

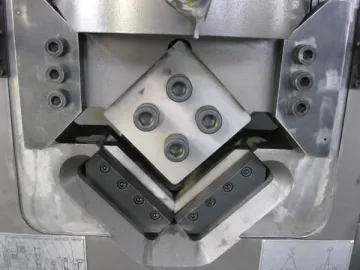

1. The slide servo drilling spindle is capable of drilling through holes, reaming holes, chamfering, and groove. It can work both cooperatively and independently.

2. The programming software is based on a Windows platform. With a CAD connection, our CNC driller can achieve quick and convenient programming and direct image previewing.

3. Our CNC plate drilling machine has T notches on the machine body and the work piece is clamped by a pressing plate.

4. In order to find the center of the work piece, there are hand-operated wheel, thimble and edge detectors available.

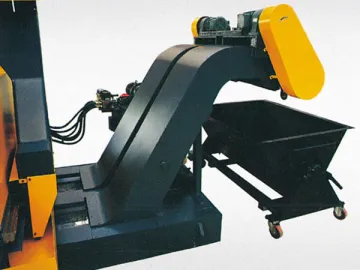

5. This CNC drilling equipment for plates has an automatic chip removal device, and it can recycle the cooling liquid.

6. Mechanical parts, hydraulic components and electric elements are all purchased from well-known companies both at home and abroad, ensuring our CNC plate drilling machines are stable.

7. This CNC processing equipment is the first choice for large scale tube plates for heat exchange, chemical, and mechanical industries.

8. Our CNC plate drilling machine can automatically find spots on both the X and Y axis to drill holes, and the rotation speed of the drilling spindle and the feedings peed can all have stepless adjustments.

Parameters| Model | TPLD2020 | TPLD2525 | TPLD3030 | |||

| Max size of workpiece (mm) | Max. center distance L×W (mm) | 2,000×2,000 | 2,500×2,500 | 3,000×3,000 | ||

| Max. thickness of workpiece (mm) | 200 | |||||

| Worktable | Width/distance of T notch | 28/500 | 28/500 | 28/500 | ||

| Drilling spindle | Quantity | One or more (according to customer’s requirement) | ||||

| Max. drilling diameter | Φ50mm | |||||

| Morse taper of spindle | #4 | |||||

| Rotation speed (rpm) | From 120 to 480 (Stepless speed adjustment) | |||||

| Max. stroke of feeding (mm) | 350 | |||||

| Feeding speed (mm/min) | From 0 to 4,000 (Stepless speed adjustment) | |||||

| Motor power (kw) | 5.5 | |||||

| Positioning precision | X axis and Y axis | ≦0.1/ (full length) | ||||

| Re-positioning precision | X axis and Y axis | ≦0.1 | ||||

| Motor power (kw) | Servo motors | X axis | 1.5 | |||

| Y axis | 1.5 | |||||

| Z axis | 1 | |||||

| Drive motor for chip collector | 0.75 | |||||

| Motor for cooling pump | 0.25 | |||||

| Type of chip collector | Chain-plate type | |||||

| Quantity of chip collector | 2 | |||||

| Chip removal speed (m/min) | 1 | |||||

| CNC system | 8055 CNC system of FAGOR,Spain | |||||

| Net weight (kg) | ≈16,000 | ≈20,000 | ≈24,000 | |||

| Dimension (L×W×H) (mm) | 4,990×5,050×3,200 | 5,490×5,550×3,200 | 5,990×6,050×3,200 | |||

| Note: Other models can be customized. | ||||||

Links:https://www.globefindpro.com/products/72294.html

-

Straightening Machine

Straightening Machine

-

TPPR103 / TPPR104 CNC Hydraulic Punching Machine

TPPR103 / TPPR104 CNC Hydraulic Punching Machine

-

TPD16 / TPD30 CNC Plate Drilling Machine

TPD16 / TPD30 CNC Plate Drilling Machine

-

TBL2532 CNC Angle Line (CNC Drilling and Metal Marking Machine)

TBL2532 CNC Angle Line (CNC Drilling and Metal Marking Machine)

-

CNC Angle Punching Line

CNC Angle Punching Line

-

TBS Series CNC Band Saw Machine

TBS Series CNC Band Saw Machine

-

TSWZ1000 / TSWZ1250 CNC Beam Drilling Line

TSWZ1000 / TSWZ1250 CNC Beam Drilling Line

-

TAPM1412 CNC Angle Line (Including CNC Metal Marking, Punching, Shearing Machine)

TAPM1412 CNC Angle Line (Including CNC Metal Marking, Punching, Shearing Machine)

-

TDJ1000 / 1250 CNC Band Saw Machine

TDJ1000 / 1250 CNC Band Saw Machine

-

CNC Press Brake

CNC Press Brake

-

TPP103 / TPP104 CNC Hydraulic Punching Machine

TPP103 / TPP104 CNC Hydraulic Punching Machine

-

Compatible BANKSTAR Printer Ribbon

Compatible BANKSTAR Printer Ribbon