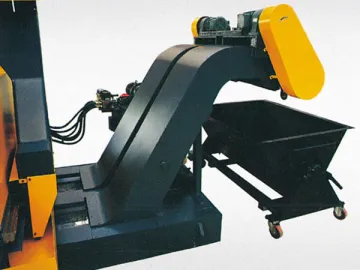

Straightening Machine

Our straightening machine can be applied to electrical, bridge, construction, tower, sheet metal, repair, and maintenance industries. This flattening machine can straighten steel plates, such as the Q235 steel plate, stainless steel plates, and 16Mn steel plates before they are welded. Our straightener is also applicable to a variety of sectional materials, including angle steel, channel steel, joist steel, square steel, round steel, steel tubes, and axis.

Features

1. With a mechanical transmission and single operating station, our straightening machine is safe, flexible and easy to operate.

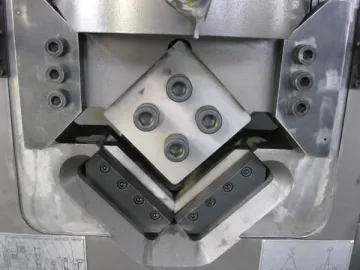

2. Our CNC straightener has a three-point type: two adjustable supporting points and one pressure point.

3. This straightening machine's body is an all steel welding structure, featuring an excellent rigidity, large bearing capacities and easy operation.

4. Our CNC flattener is equipped with individual adjustment devices for width of the closure and roller bed bracket systems.

5. The width of closure is adjustable during operation, which brings a great level of convenience and significantly improve the working efficiency.

Parameters| Model | TXZ20 | |

| Max. size of workpiece (mm) | Angle steel | From 40×40×3 to 200×200×20 |

| Round steel | Below 150 | |

| Channel steel | Below 260 | |

| Band steel | Below 260 | |

| Square steel | Below 150 | |

| Max. force of straightening (kn) | 1,000 | |

| Working stroke of slider (mm) | 20 | |

| Times of slider's stroke (min-1) | 25 | |

| Max. width of closure (mm) | 220 | |

| Adjustable variable of width (mm) | 100 | |

| Distance from the slider's center to machine body (mm) | 135 | |

| Max. bearable center distance of slider (mm) | 800 | |

| Center height of slider (mm) | 200 | |

| Quantity of station | 1 | |

| Motor power (kw) | 7.5 | |

| Dimension L× W×H (mm) | 2,450×1,680×1,440 | |

| Weight (kg) | ≈3,000 | |

Links:https://www.globefindpro.com/products/72295.html

-

TPPR103 / TPPR104 CNC Hydraulic Punching Machine

TPPR103 / TPPR104 CNC Hydraulic Punching Machine

-

TPD16 / TPD30 CNC Plate Drilling Machine

TPD16 / TPD30 CNC Plate Drilling Machine

-

TBL2532 CNC Angle Line (CNC Drilling and Metal Marking Machine)

TBL2532 CNC Angle Line (CNC Drilling and Metal Marking Machine)

-

CNC Angle Punching Line

CNC Angle Punching Line

-

TBS Series CNC Band Saw Machine

TBS Series CNC Band Saw Machine

-

TPPR103 / TPPR104 CNC Plate Punching Machine

TPPR103 / TPPR104 CNC Plate Punching Machine

-

TPLD2020 / TPLD2525 / TPLD3030 CNC Plate Drilling Machine

TPLD2020 / TPLD2525 / TPLD3030 CNC Plate Drilling Machine

-

TSWZ1000 / TSWZ1250 CNC Beam Drilling Line

TSWZ1000 / TSWZ1250 CNC Beam Drilling Line

-

TAPM1412 CNC Angle Line (Including CNC Metal Marking, Punching, Shearing Machine)

TAPM1412 CNC Angle Line (Including CNC Metal Marking, Punching, Shearing Machine)

-

TDJ1000 / 1250 CNC Band Saw Machine

TDJ1000 / 1250 CNC Band Saw Machine

-

CNC Press Brake

CNC Press Brake

-

TPP103 / TPP104 CNC Hydraulic Punching Machine

TPP103 / TPP104 CNC Hydraulic Punching Machine