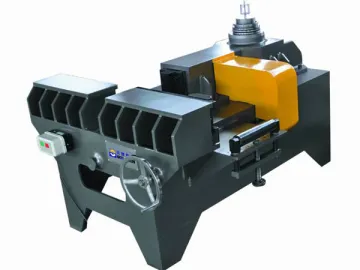

TPD16 / TPD30 CNC Plate Drilling Machine

Application

Our CNC plate drilling machine with four processing positions can be used for drilling holes on junction and bed plates in steel structure, steel tower, bridge and machining industries.

Features

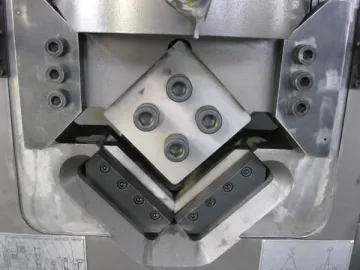

1. Our CNC drill press is equipped with 4 processing positions and 12 hydraulic clamps. These can accommodate 4 sets of work pieces, and our CNC drilling machine allows the work pieces to be assembled and disassembled while drilling.

2. The programming software is based on a Windows platform. With a CAD connection, our CNC drilling machine can achieve quick and convenient programming as well as direct image previewing.

3. The CNC drilling spindle can control the depth of the holes, and is capable of drilling blind holes, reaming holes and chamfering.

4. Our steel plate driller can automatically find spots on the X and Y axis to drill holes.

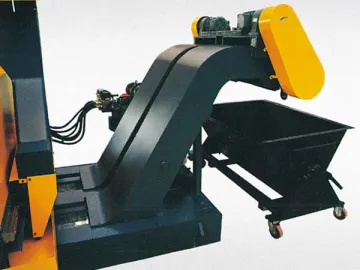

5. This CNC plate drilling machine has automatic chip removal devices, and it can recycle the cooling liquid.

6. Each of the mechanical parts, hydraulic components and electrical elements are purchased from well-known companies from here in China and abroad.

7. As the entire machine has an optimal and integrated design, it requires no equipment foundations.

Parameters| Model | TPD16 | TPD30 | ||

| Max size of workpiece (mm) | One piece | 1,600×1,000 | 3,000×1,600 | |

| two pieces | 800×1,000 | 1,500×1,600 | ||

| four pieces | 800×500 | 1,500×800 | ||

| Max. thickness of workpiece | 100mm; thinner plates can have overlap processing | |||

| Morse taper of spindle | #4 | |||

| Max. drilling diameter | Φ50 | |||

| Drilling spindle | Rotation speed(rpm) | From 120 to 560 (Stepless speed adjustment) | ||

| Max. stroke of feeding (mm) | 240 | |||

| Feeding speed(mm/min) | From 20 to 200 (Stepless speed adjustment) | |||

| Motor power(kw) | 5.5 | |||

| Hydraulic clamps | Thickness of clamping (mm) | From15 to 100 | ||

| Quantity of clamps | 12 | |||

| Clamping force (kn/each) | 7.5 | |||

| Motor power(kw) | Servo motors | X axis | 1.3 | |

| Y axis | 1.3 | |||

| Z axis | 0.85 | |||

| Motor for hydraulic system | 2.2, 3.7 | |||

| Drive motor for chip collector | 2×0.4 | |||

| Motor for cooling pump | 0.25 | |||

| Net weight(kg) | 4,000 | 8,500 | ||

| Dimension(L×W×H)(mm) | 5,810×3,660×2,790 | 7,490×4,460×2,790 | ||

Links:https://www.globefindpro.com/products/72297.html

-

TBL2532 CNC Angle Line (CNC Drilling and Metal Marking Machine)

TBL2532 CNC Angle Line (CNC Drilling and Metal Marking Machine)

-

CNC Angle Punching Line

CNC Angle Punching Line

-

TBS Series CNC Band Saw Machine

TBS Series CNC Band Saw Machine

-

TPPR103 / TPPR104 CNC Plate Punching Machine

TPPR103 / TPPR104 CNC Plate Punching Machine

-

TPD2010 / TPD2012 / TPD2016 CNC Plate Drilling Machine

TPD2010 / TPD2012 / TPD2016 CNC Plate Drilling Machine

-

TBD200/3, TBD1010 CNC Beam Drilling Line

TBD200/3, TBD1010 CNC Beam Drilling Line

-

TPPR103 / TPPR104 CNC Hydraulic Punching Machine

TPPR103 / TPPR104 CNC Hydraulic Punching Machine

-

Straightening Machine

Straightening Machine

-

TPLD2020 / TPLD2525 / TPLD3030 CNC Plate Drilling Machine

TPLD2020 / TPLD2525 / TPLD3030 CNC Plate Drilling Machine

-

TSWZ1000 / TSWZ1250 CNC Beam Drilling Line

TSWZ1000 / TSWZ1250 CNC Beam Drilling Line

-

TAPM1412 CNC Angle Line (Including CNC Metal Marking, Punching, Shearing Machine)

TAPM1412 CNC Angle Line (Including CNC Metal Marking, Punching, Shearing Machine)

-

TDJ1000 / 1250 CNC Band Saw Machine

TDJ1000 / 1250 CNC Band Saw Machine