TPM Series Multi Spindle CNC Drilling Machine

Application

Our multi spindle CNC drilling machine consists of the gantry, machine body, and longitudinal sliding table, vertical ram drilling power control box, work table, chip collector, hydraulic press system, cooling system, centralized lubrication system, electrical system, and pneumatic system.

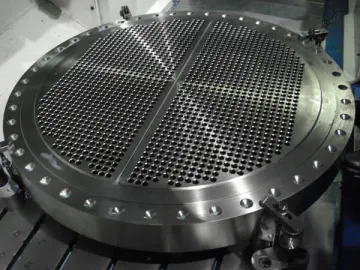

This CNC drilling equipment can be perfectly used to drill holes on the tube, baffle, and flange plates in petrochemical, boiler, refrigeration, and wind power industries. It can also be used on the junction plate of steel structures in construction, bridge building, and tower building.

Features

Machine body and longitudinal sliding table

The machine body of our multi spindle CNC drilling machine has flexible and highly precise linear roller guide pairs from Hiwin in Taiwan. The drive, featuring medium capacity and inertia, low velocity and large torque comes from Panasonic in Japan, and is driven by the synchronous belt connected to the AC servo motor and precise-finish grade ball screw pair with coarse pitch from 1 F in Germany.

Gantry and horizontal sliding table

There are two sliding plates on the cross beam on our CNC high speed driller's gantry. The sliding plates are guided by the high precision rolling guide pairs from Hiwin in Taiwan. The drive features medium capacity and inertia, low velocity, and a large torque, and is from Panasonic in Japan. The drive is driven by the synchronous belt connected to the AC servo motor and precise-finish grade ball screw pair with coarse pitch from 1 F in Germany, which effectively ensures the high working precision.

Vertical Ram drilling power control box

The vertical lift of our CNC drilling press is guided by roller linear guide pairs from Schneeberger in Switzerland. The drive, which features medium capacity and inertia, low velocity, and a large torque, and is from Panasonic in Japan. The drive is driven by the synchronous belt connected to the AC servo motor and precise-finish grade ball screw pair with coarse pitch from 1 F in Germany, which effectively ensures the high working precision.

Our multi spindle CNC drilling machine’s drilling spindle, having a step free speed adjustment, low velocity and large torque is driven by the synchronous belt connected to the high-power variable frequency motor. The drilling spindle can support a heavy cut load and is applicable to carbide allow cutters in high-speed machining.

Additionally, the drilling spindle of this CNC drilling machine is a precision inner-cooled spindle from Taiwan. It has a BT50 spindle taper and Belleville spring automatic broach mechanism. The drilling spindle can also be installed with drills or milling centers with an extension rod. It also has a hydraulic cylinder to loosen the cutter, which makes changing the tool holder convenient.

The gantry, machine body and worktable of our multi spindle CNC drilling machine are all welded by premium steel plates. We adopt high temperature annealing to eliminate stress on the steel plate before use, which means we can then carry out the finish machining to ensure the stability and precision of the machine.

There are several horizontal T notches on the integral worktable of our multi-spindle CNC drilling machine. They are used to clamp the fixtures and tube plate.

Our multi-spindle CNC drilling machine has 6 CNC axles, FAGOR8055 CNC system from Spain, RS232 interface and LCD screen. The drilling coordinate can achieve direct conversion between CAD/CAM. This CNC machinery for steel plate also has rechecking and previewing of the hole location before drilling.

There are automatic chip collectors on both sides of the worktable. We use a water cooling system and provide the supply, recycling, and filtration systems for the cooling liquid.

The magnetic valves of the multi spindle CNC drilling machine’s hydraulic system are all stable, and are imported from the Italian company ATOS.

There are protective covers on the guide rails and screws for both the X and Y axis. The protective covers on the X axis are for steel plates, and the protective covers on the Y axis are for organ protection.

We use high quality imported key components and parts in order to guarantee our CNC drilling machine is reliable. Please refer to the chart for main configurations.

Parameters| Model | TPM4040 | TPM5050 | TPM6060 | |

| Max. size of workpiece(mm) | Max. center distance L×W(mm) | 4,000×4,000 | 5,000×5,000 | 6,000×6,000 |

| Max. thickness of workpiece(mm) | 250 | |||

| Worktable | Width/distance of T groove(mm) | 28/500 | ||

| Drilling spindle | Quantity | 2 or more | ||

| Spindle taper | BT50 | |||

| Max. drilling diameter (mm) | Φ40 (carbide drill)Φ50(HSS twist drill) | |||

| Rotation speed (stepless)(r/min) | From 30 to 2,800 | |||

| Motor power of spindles(kw) | 22/33kw | |||

| Distance from the spindle's bottom end face to the worktable's surface (mm) | From 300 to 800 | |||

| Longitudinal movement of gantry (X axis) | Max. stroke (mm) | 4,000 | 5,000 | 6,000 |

| Feeding speed on X axis(m/min) | From 0 to 8 | |||

| Servo motor power on X axis(kw)/ torque(nm) | 2×3kw/28.4nm | |||

| Horizontal movement of gantry (Yaxis) | Max. distance between two spindles (mm) | 4,000 | 5,000 | 6,000 |

| Feeding speed on Y axis(m/min) | From 0 to 8 | |||

| Servo motor power on Y axis(kw) | 2×3kw/28.4nm | |||

| Vertical movement of gantry (Zaxis) | Max. stroke on Z axis (mm) | 500 | ||

| Feeding speed on Z axis(m/min) | From 0 to 5 | |||

| Servo motor power on Z axis(kw)/ torque(nm) | 2×3kw/28.4nm | |||

| Positioning precision | X axis and Y axis | ≤0.1/ (full length) | ||

| Re-positioning precision | X axis and Y axis | ≤0.05 | ||

| Hydraulic system | Hydraulic pump pressure (Mpa)/ flow (L/min) | 6.5 /25 | ||

| Hydraulic pump motor power(kw) | 3 | |||

| Chip removal and cooling | Type of chip collector | Chain-plate type | ||

| Quantity of chip collector | 2 | |||

| Chip removal speed (m/min) | 1 | |||

| Motor power for chip collector (kw) | 2×0.75 | |||

| Motor power for inner cooling water pump (kw) | 3 | |||

| Motor power for external cooling water pump(kw) | 0.75 | |||

| Auto lubrication system | Lubrication pressure(MPa) | 2 | ||

| Injection flow (ml) | 0.1 | |||

| Lubrication cycle(min) | From 6 to 10 | |||

| Dimension (L×W×H) (m) | Appr.7.8×6.1×3.6 | Appr.8.8×7.1×3.6 | Appr.10×9×3.6 | |

| Weight (t) | Appr. 40 | Appr. 48 | Appr. 55 | |

Links:https://www.globefindpro.com/products/72306.html

-

TBL1412 / TBL2020 CNC Angle Line (Including CNC Metal Shearing, Punching, Marking Machine)

TBL1412 / TBL2020 CNC Angle Line (Including CNC Metal Shearing, Punching, Marking Machine)

-

TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

-

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

-

TPPRD103 / TPPRD104 CNC Punching Drilling Machine

TPPRD103 / TPPRD104 CNC Punching Drilling Machine

-

TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

-

TSWZ400-9 Model CNC Beam Drilling Line

TSWZ400-9 Model CNC Beam Drilling Line

-

Hydraulic Marking Machine

Hydraulic Marking Machine

-

TPPRD103 / TPPRD104 CNC Hydraulic Punching Drilling Machine

TPPRD103 / TPPRD104 CNC Hydraulic Punching Drilling Machine

-

TBD200/3, TBD1010 CNC Beam Drilling Line

TBD200/3, TBD1010 CNC Beam Drilling Line

-

TPD2010 / TPD2012 / TPD2016 CNC Plate Drilling Machine

TPD2010 / TPD2012 / TPD2016 CNC Plate Drilling Machine

-

TPPR103 / TPPR104 CNC Plate Punching Machine

TPPR103 / TPPR104 CNC Plate Punching Machine

-

TBS Series CNC Band Saw Machine

TBS Series CNC Band Saw Machine