TBL1412 / TBL2020 CNC Angle Line (Including CNC Metal Shearing, Punching, Marking Machine)

Our CNC metal punching, marking, shearing machine for angle steels uses a double blade and successfully manages to perform well when it comes to cutting the corners of angled steel holders, splints, stringers, and trusses in steel structures.

This CNC angle line comes equipped with a double blade. It is an indispensable CNC machining center for the steel structure industry. Our CNC machinery for angle steel is also applicable to the angle steel communication towers and other tasks.

Components

Horizontal material conveyor, Rotating blade system, Infeed channel, CNC infeed trolley, Punching unit, Marking unit, Shearing unit, Outfeed channel, Hydraulic power unit, Control cabinet, Pneumatic system.

| Model | TBL1412 | TBL2020 |

| Functions | Punching, marking, shearing | Punching, marking, shearing |

| Processing range (mm) | From 40×40×3 to 140×140×12 | From 50×50×3 to 200×200×20 |

| Max. punching capacity (diameter × thickness) (mm) | Ф26×12 | Φ26х20 |

| Punching force (kn) | 600 | 1,000 |

| Marking force (kn) | 800 | 800 |

| Shearing force (kn) | 900 | 1,400 |

| Max. length of workblank (m) | 12 | 14 |

| Max. length of finished product (m) | 12 | 14 |

| Number of punching head on each side | 2 | 3 |

| Number of character marking group | 4 | 4 |

| Dimension of character (mm) | 14×10×19 | 14×10×19 |

| Number of CNC axes | 3 | 3 |

| Cutting mode | Dual blades cutting | Dual blades cutting |

| Feeding speed of angle steel (m/min) | 60 | 60 |

| Processing precision | In accordance with GB2694-2010 | |

| Programming mode | Keyboard input, RS232 interface, floppy disk and USB interface | |

| Program function | Error display | |

| Working environment | Temperature: from -10° to 40°; Voltage: 380V 50HZ three phase; Voltage range: ±10% | |

| Dimension(mm) | 25,400×7,000×2,200 | 32,000×7,000×2,600 |

Scan QR to Read

Links:https://www.globefindpro.com/products/72307.html

Links:https://www.globefindpro.com/products/72307.html

Recommended Products

-

TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

-

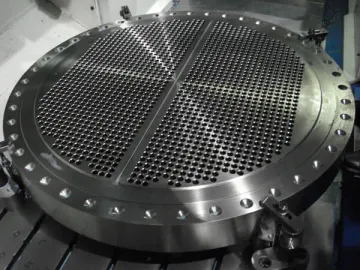

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

-

TPPRD103 / TPPRD104 CNC Punching Drilling Machine

TPPRD103 / TPPRD104 CNC Punching Drilling Machine

-

TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

-

TSWZ400-9 Model CNC Beam Drilling Line

TSWZ400-9 Model CNC Beam Drilling Line

-

TPLD Series Multi Spindle CNC Drilling Machine

TPLD Series Multi Spindle CNC Drilling Machine

-

TPM Series Multi Spindle CNC Drilling Machine

TPM Series Multi Spindle CNC Drilling Machine

-

Hydraulic Marking Machine

Hydraulic Marking Machine

-

TPPRD103 / TPPRD104 CNC Hydraulic Punching Drilling Machine

TPPRD103 / TPPRD104 CNC Hydraulic Punching Drilling Machine

-

TBD200/3, TBD1010 CNC Beam Drilling Line

TBD200/3, TBD1010 CNC Beam Drilling Line

-

TPD2010 / TPD2012 / TPD2016 CNC Plate Drilling Machine

TPD2010 / TPD2012 / TPD2016 CNC Plate Drilling Machine

-

TPPR103 / TPPR104 CNC Plate Punching Machine

TPPR103 / TPPR104 CNC Plate Punching Machine

Hot Products