TPPRD103 / TPPRD104 CNC Punching Drilling Machine

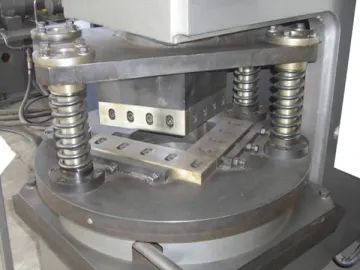

Our CNC punching drilling machine for plates has three dye stations. The three stations can accommodate three sets of punching dyes, which enables the machine to punch three holes with different diameters on the work piece. The three dye stations can also be installed with two sets of punching dyes, and one character box, which can mark on the work piece while punching.

It is easy to change dyes, and the marked characters are clear. Operating staff has only to enter the work piece dimensions in the principal computer, and the machine will then work automatically. It can also memorize the date for repeated use in the future. This CNC machinery for plates is excellent for punching and marking junction plates in the tower and sheet metal processing industries.

Features

1. With a strengthened machine body and enlarged oil cylinder, our enhanced CNC processing machine has a better punching force, which makes it suitable for the processing of steel plates with higher strength.

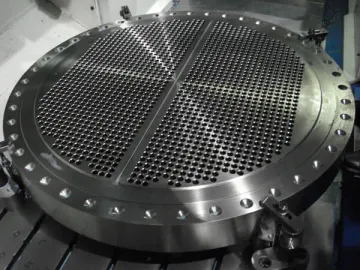

2. With advanced CNC technology and a servo motor controlled feeding system, our CNC punching drilling machine has better efficiency and generate work pieces that are more accurate.

3. When programming, just enter the work piece information, including bore diameter, stadia and quantity. You can also use CAD/CAM to convert data directly.

4. The drilling function of our enhanced CNC machinery has several different capabilities, including fast forward noncutting stokes, low speed feeding and high speed return strokes. All of these effectively improve work piece efficiency.

5. With its main functioning parts put together in a modular assembly, our CNC punching drilling machine requires very little maintenance.

6. Our CNC drilling equipment can perform self-diagnostic fault findings.

7. The X and Y axes both have higher precision as they are equipped with a servo motor, ball screw and linear guideway.

8. The workbench is equipped with a stainless steel plate, giving it a better appearance and more practicality.

Parameters of CNC Punching, Drilling, and Marking Machine| Model | TPPRD103 | TPPRD104 | |

| Max. dimension of workpiece (L×W) (mm) | 1,500×800 | 1,500×1,000 | |

| Max. punching diameter (mm) | Φ26 | ||

| Thickness of punched-plate (mm) | From 5 to 25(Q345, 16Mn)From 5 to 20(Q420) | From 5 to 25(Q345, 16Mn)From 5 to 20(Q420) | |

| Max. drilling diameter(mm) | Φ50 | ||

| Max. thickness of drilled-plate(mm) | 40 | ||

| Punching force (kn) | 1,200 | ||

| Marking force (kn) | 1,000 | ||

| Min. distance between hole and plate's edge (mm) | Punching | 25 | |

| Drilling | Depending on the hole diameter | ||

| Dimension of character (mm) | 14×10×19 / 20×12×19 | ||

| Number of character | 16 / 14 | ||

| Number of die station | 4 | ||

| Feeding speed of drilling head (mm/min) | From 25 to 280 | ||

| Stroke of drilling spindle (mm) | 180 | ||

| Rotation speed of drilling spindle(r/min) | From 120 to 560 | ||

| Processing precision | In accordance with GB2694 | ||

| Programming mode | Keyboard input, RS232 interface, floppy disk and USB interface | ||

| Dimension (L×W×H) (mm) | 3,300×3,200×2,600 | 3,700×3,200×2,600 | |

| Weight (kg) | Appr. 7,000 | Appr. 7,400 | |

Links:https://www.globefindpro.com/products/72310.html

-

TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

-

TSWZ400-9 Model CNC Beam Drilling Line

TSWZ400-9 Model CNC Beam Drilling Line

-

TPLD Series Multi Spindle CNC Drilling Machine

TPLD Series Multi Spindle CNC Drilling Machine

-

Compatible AMT Printer Ribbon

Compatible AMT Printer Ribbon

-

Hydraulic Notching Machine

Hydraulic Notching Machine

-

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

-

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

-

TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

-

TBL1412 / TBL2020 CNC Angle Line (Including CNC Metal Shearing, Punching, Marking Machine)

TBL1412 / TBL2020 CNC Angle Line (Including CNC Metal Shearing, Punching, Marking Machine)

-

TPM Series Multi Spindle CNC Drilling Machine

TPM Series Multi Spindle CNC Drilling Machine

-

Hydraulic Marking Machine

Hydraulic Marking Machine

-

TPPRD103 / TPPRD104 CNC Hydraulic Punching Drilling Machine

TPPRD103 / TPPRD104 CNC Hydraulic Punching Drilling Machine