TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

Our CNC metal punching, marking, shearing machine for single blade angle steels is an automatic CNC system that is specially made for angle steel communication towers and other industries.

It is ideal to assist in the processing of materials into precision finished products in the most effective manner. Our CNC angle line can perfectly replace manual work and successfully achieve automatic punching, marking and shearing.

Features

1. We use CNC technology in this automatic angle steel machining equipment. Its feeding system is controlled by a servo motor, which gives it a high efficiency and generates work pieces with stable precision.

2. All hydraulic parts, pneumatic components and electrical elements are imported and have a stable quality.

3. This automatic CNC angle line's programming is simple. All data generated from the sample software can be directly used.

4. In addition to being easy to operate, it can be used with the Chinese language or English language, as well as displaying the work piece's figure.

5. This unit has superb rigidity, due to its brand new, closed frame. The marking stadia can be set at will.

6. It functions with single blade cutting, which saves material usage.

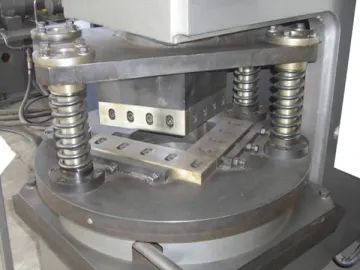

Components

Horizontal material conveyor, Rotating loading system, Infeed channel, CNC infeed trolley, Punching unit, Marking unit, Shearing unit, Outfeed channel, Hydraulic power unit, Control cabinet, Pneumatic system.

| Model | TBL0707/TAPM0707 |

| Functions | Punching, marking, shearing |

| Processing range (mm) | From 40×40×3 to100×100×10 |

| Max. punching capacity (diameter×thickness) (mm) | Φ26×10 (8mm, Q345) |

| Punching force (kn) | 600 |

| Marking force (kn) | 800 |

| Shearing force (kn) | 1,000 (Q345, 90×8mm) |

| Max. length of workblank (m) | 12 |

| Max. length of finished product (m) | 12 |

| Number of punching head on each side | 2 |

| Number of character marking group | 4 |

| Dimension of character (mm) | 14×10×19 |

| Number of CNC axes | 3 |

| Cutting mode | Single blade cutting |

| Feeding speed of angle steel (m/min) | 80 |

| Processing precision | In accordance with GB2694 |

| Program function | Real-time monitor, Error display |

| Programming mode | Keyboard input, RS232 interface, floppy disk and USB interface |

| Working environment | Temperature:-10° to 40°; Voltage: 380V 50HZ Three phase; Voltage range: ±10% |

| Dimension (mm) | 23,000×6,500×2,500 |

| Air supply (MPa) | Appr. 1 |

| Weight (kg) | Appr. 10,000 |

| Total power (kw) | Appr. 38 |

Links:https://www.globefindpro.com/products/72311.html

-

TSWZ400-9 Model CNC Beam Drilling Line

TSWZ400-9 Model CNC Beam Drilling Line

-

TPLD Series Multi Spindle CNC Drilling Machine

TPLD Series Multi Spindle CNC Drilling Machine

-

Compatible AMT Printer Ribbon

Compatible AMT Printer Ribbon

-

Hydraulic Notching Machine

Hydraulic Notching Machine

-

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

-

TSWZ700 CNC Beam Drilling Line

TSWZ700 CNC Beam Drilling Line

-

TPPRD103 / TPPRD104 CNC Punching Drilling Machine

TPPRD103 / TPPRD104 CNC Punching Drilling Machine

-

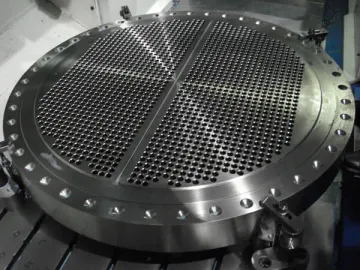

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

-

TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

TAPM2020 CNC Angle Line (Including CNC Structural Steel Punching, Marking, Shearing Machine)

-

TBL1412 / TBL2020 CNC Angle Line (Including CNC Metal Shearing, Punching, Marking Machine)

TBL1412 / TBL2020 CNC Angle Line (Including CNC Metal Shearing, Punching, Marking Machine)

-

TPM Series Multi Spindle CNC Drilling Machine

TPM Series Multi Spindle CNC Drilling Machine

-

Hydraulic Marking Machine

Hydraulic Marking Machine