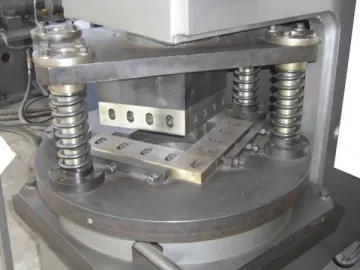

Hydraulic Notching Machine

Our hydraulic notching machine is used for corner cutting in angle steel, and can be configured with molds utilize punching and marking capabilities.

Features

1. This CNC corner cutter has an open C structure, and can make right angle, dual blade corner cutting and rotary multi-directional corner cutting.

2. With an adjustable rotary form work, it can cut angle steels with a variety of angles.

3. The angle steel being cut does not need to be moved or rotated, which means our hydraulic marking machine requires a smaller working space and can avoid cutting errors.

4. Our hydraulic grooving machine can achieve marking and punching when corresponding molds are installed.

5. As it is equipped with an optical registration device, our hydraulic notching machine can guarantee a more accurate angle for corner cutting.

Parameters| Model | TQJ140 | TQJ160 | TQJ200 (Four-column type) |

| Functions | Used for cutting corner of angle steel in tower industry | ||

| Nominal pressure(kn) | 800 | 1,000 | 1,600 |

| Stroke of oil cylinder (mm) | 50 | 50 | 50 |

| Times of stroke(min-1) | From 20 to 25 | From 20 to 25 | From 20 to 25 |

| Motor power (kw) | 15 | 15 | 22 |

| Scope of angles (mm) | From 40×40×3 to 140×140×12 | From 40×40×3 to160×160×16 | From 40×40×3 to200×200×20 |

| Rotary angle of cutting mould | 360° manual | ||

| Dimensions of cutting mould (mm) | 650×650×500 | 700×700×500 | 830×700×600 |

| Dimensions of machine L×W×H(mm) | 1,270×1,020×1,800 | 1,300×1,020×1,880 | 1,370×1,120×1,900 |

Links:https://www.globefindpro.com/products/72315.html

-

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

-

TSWZ700 CNC Beam Drilling Line

TSWZ700 CNC Beam Drilling Line

-

TPPD103 / TPPD104 CNC Hydraulic Punching Drilling Machine

TPPD103 / TPPD104 CNC Hydraulic Punching Drilling Machine

-

CNC H-Beam Beveling Machine

CNC H-Beam Beveling Machine

-

TBL2020 CNC Angle Line (Including Structural Steel Punching, Marking, Shearing Machine)

TBL2020 CNC Angle Line (Including Structural Steel Punching, Marking, Shearing Machine)

-

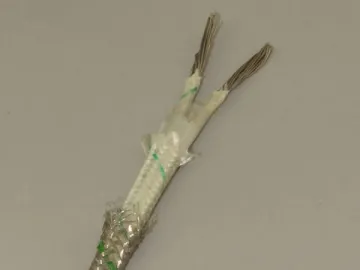

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

-

Compatible AMT Printer Ribbon

Compatible AMT Printer Ribbon

-

TPLD Series Multi Spindle CNC Drilling Machine

TPLD Series Multi Spindle CNC Drilling Machine

-

TSWZ400-9 Model CNC Beam Drilling Line

TSWZ400-9 Model CNC Beam Drilling Line

-

TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

TBL0707 / TAPM0707 CNC Angle Line(Including CNC Metal Punching, Marking, Shearing Machine)

-

TPPRD103 / TPPRD104 CNC Punching Drilling Machine

TPPRD103 / TPPRD104 CNC Punching Drilling Machine

-

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine

TPM2020 / TPM2525 / TPM3030 CNC Steel Plate Drilling Machine