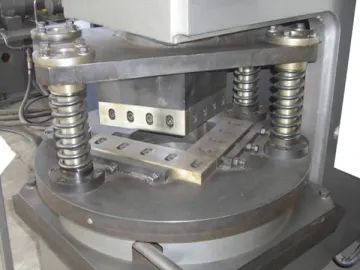

CNC H-Beam Beveling Machine

Application

Our CNC H-beam beveling machine can be applied to the edge milling and chamfering of H- beam and box beams in a variety of industries.

Features

1. In one stroke, the milling spindle of our CNC H-Beam beveling machine can complete the edge milling of H-beam's flange, chamfering and processing of arc-shaped notches on the web.

2. Our CNC edge planning machine can adjust the size of the notch and efficiently generate work pieces with excellent surface quality.

3. There are two types of CNC H-beam beveling machines: a single side twin column with tow tri-axial milling spindles, and a double sided four column with four tri-axial milling spindles.

4. The machine body and the columns all have superb rigidity and strength. The hydraulic clamping system is stable and reliable, and the vibration during processing creates very little noise.

5. The indexable insert is adopted to the edge milling and chamfering, which can extend the service life of the blade.

6. Our CNC machine for H-beam has a mechanical feeding mechanism, which can automatically adjust the feeding speed and guarantee the reliability and safety of material feeding.

7. Our CNC H-beam beveling machine adopts automatic positioning devices, meaning there is no need for manual adjustments.

8. Our CNC beveling equipment has a PLC control system, and the programming and parameter output can be achieved via the touch screen.

9. The main mechanical parts are all purchased from internationally known companies.

ParametersTBM38 CNC H-Beam Beveling Machine

| Model | TBM38/6 | TBM38/12 | |

| Size of H-beams | Flange width (mm) | From 220 to1,000 | |

| Web height (mm) | From 100 to 600 | ||

| Flange thickness (mm) | From 6 to 38 | ||

| End-incline (mm) | 300 | ||

| Length ( mm) | 400 | ||

| Milling unit with three spindles | Quantity | 2 | 4 |

| Rotation speed of spindles ( r/min) | 250 | ||

| Motor power of spindles ( kw) | 2×7.5 | 4×7.5 | |

| Up/down speed (mm/min) (frequency conversion, CNC) | From 125 to 500 | ||

| Motor power for up and down (kw) | 2×1.5 | 4×1.5 | |

| Slipway | Longitudinal slipway stroke (mm) | 300 | |

| Horizontal slipway stroke (mm) | 850 | ||

| Slipway moving speed (mm/min) (frequency conversion, CNC) | From 400 to 1,600 | ||

| Motor power for slipway (kW) | 2×0.25 | 4×0.25 | |

| Vertical clamp | Vertical clamping speed (mm/min) | 450 | |

| Motor power (kw) | 2×0.37 | 4×0.37 | |

| Airdraulic pressure-amplifier | Boost pressure ratio | 11:1 | |

| Clamp force (kW) | From 3.5 to 8 | ||

| Auto stopper-mechanism | Adjustment (mm) | From 0 to 40 | |

| Motor power (kw) | 2×0.04 | 4×0.04 | |

| Rollaway nest | The length of infeed rollaway nest (mm) | 1×5,060 | 2×5,060 |

| Feeding speed (m/min) (frequency conversion) | From 7 to 28 | ||

| Motor power for infeed rollaway nest (kw) | 1×0.05 | 2×0.05 | |

| Motor power for transmitting rollaway nest (kw) | 1×0.25 | 4×0.25 | |

| Motor power for supporting ball screw (kw) | 2×0.09 | 4×0.09 | |

| Motor power for inclined rollaway nest (kw) | -- | 4×0.09 | |

| Dimension (L×W×H ) (m) | 7.3×2.9×2 | 14.6×2.9×2 | |

| Weight (kg) | Appr.5,000 | Appr.10,000 | |

| Model | TBM55/6 | |

| Size of H-beams | Flange width (mm) | From 220 to 1,250 |

| Web height (mm) | From 100 to 600 | |

| Flange thickness (mm) | From 10 to 55 | |

| End-incline (mm) | >400 | |

| Milling head | Quantity | 2 |

| Quantity of milling cutter | 6 | |

| Rotation speed of spindle (r/min) | 267 | |

| Feeding speed (mm/min) | From 0 to 300 | |

| Motor power of spindle (kw) | 2×15 | |

| CNC slipway | Horizontal slipway stroke | 1,050mm |

| Longitudinal slipway stroke | 300mm | |

| Slipway moving speed | From 150 to1,000 mm/min | |

| Electrical system | Control mode | PLC |

| Dimension (m) | 7×3.9×2.8 | |

| Weight (kg) | 11,000 | |

Links:https://www.globefindpro.com/products/72319.html

-

TBL2020 CNC Angle Line (Including Structural Steel Punching, Marking, Shearing Machine)

TBL2020 CNC Angle Line (Including Structural Steel Punching, Marking, Shearing Machine)

-

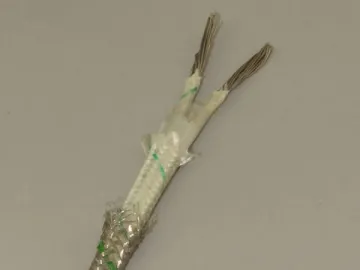

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

-

Sheet Metal Shearing Machine

Sheet Metal Shearing Machine

-

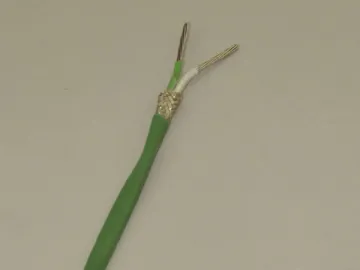

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.43mm)

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.43mm)

-

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x24/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x24/0.2mm)

-

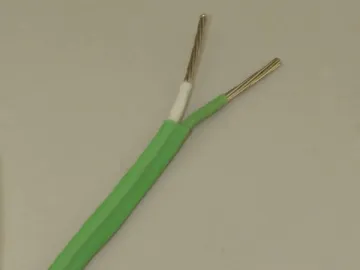

KX Thermocouple Extension Wire(FEP Insulated Wire 2x32/0.2mm)

KX Thermocouple Extension Wire(FEP Insulated Wire 2x32/0.2mm)

-

TPPD103 / TPPD104 CNC Hydraulic Punching Drilling Machine

TPPD103 / TPPD104 CNC Hydraulic Punching Drilling Machine

-

TSWZ700 CNC Beam Drilling Line

TSWZ700 CNC Beam Drilling Line

-

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

-

Hydraulic Notching Machine

Hydraulic Notching Machine

-

Compatible AMT Printer Ribbon

Compatible AMT Printer Ribbon

-

TPLD Series Multi Spindle CNC Drilling Machine

TPLD Series Multi Spindle CNC Drilling Machine