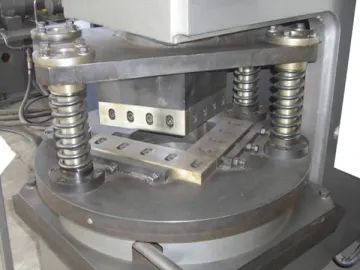

TBL2020 CNC Angle Line (Including Structural Steel Punching, Marking, Shearing Machine)

Our TBL2020 CNC angle line for angled steel is great for communication tower production, along with other industries, and can achieve fully automatic marking, punching and shearing on angled steel

Features

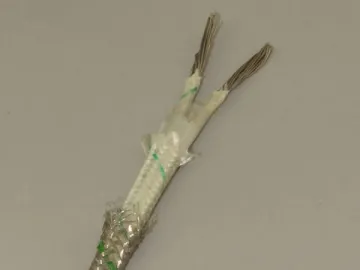

1. We adopt a shielding twin twisted cable that is imported from Germany to the key cables like the encoder cable on the trolley and communication cable of PLC. By utilizing superior cables, our CNC processing equipment can get rid of signal interference and maintain accuracy.

2. All marking, punching and shearing is automatically controlled.

3. When programming, you need only enter the work piece's information, including dimension, bore diameter, staid and quantity. You can also use CAD/CAM to convert the data directly.

4.Our CNC shearing equipment has four functions for cutting, each of which can be chosen at will, and can process material with fixed lengths while functioning under the non-cutting setting.

1). Front cutting

2). Rear cutting

3). Non-cutting stroke

4). Cutting on both ends

5.The marking unit has a brand new closed frame that features excellent rigidity and the marking stadia can be set randomly.

6. Our CNC structural steel punching equipment’s hydraulic power unit is water cooled.

7. This CNC angle line comes equipped with the self-diagnostic function to search for faults.

8.We adopt CNC technology for this automatic angle steel machining equipment. Its feeding system is controlled by the servo motor, which gives it a high efficiency and generates work pieces with stable precision.

9.Key components, especially for the hydraulic system, pneumatic components and electrical elements are all imported and are of a reliable quality.

10.Our equipment's computers can support both the Chinese and English languages, making it easy to operate, and can display work piece figures.

11.Programming is simple, and data generated from the sample software can be directly used.

Parameters of TBL2020 CNC Processing Equipment| Model | TBL2020 |

| Functions | Punching, marking, shearing |

| Processing range (mm) | From 63×63×4 to 200×200×20 |

| Max. punching capacity (diameter×thickness) (mm) | Ф26×20 |

| Punching force (kn) | 1,000 |

| Marking force (kn) | 800 |

| Shearing force (kn) | 1,400 |

| Max. length of workblank (m) | 14 |

| Max. length of finished product (m) | 14 |

| Number of punching head on each side | 3 |

| Number of character marking group | 4 |

| Dimension of character (mm) | 14×10×19 (Customizable) |

| Number of CNC axes | 3 |

| Cutting mode | Dual blades cutting |

| Feeding speed of angle steel (m/min) | 40 |

| Processing precision | In accordance with GB2694-2010 |

| Program function | Keyboard input, RS232 interface, floppy disk and USB interface |

| Programming mode | Error language display |

| Working environment | Temperature:-10° to 40°; Voltage: 380V 50HZ Three phase; Voltage range: ±10% |

| Dimension (mm) | 32,000×7,500×2,350 |

| Air supply (MPa) | Appr. 1 |

| Weight (kg) | Appr.14,500 |

| Total power (kw) | Appr. 43 |

Links:https://www.globefindpro.com/products/72320.html

-

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

-

Sheet Metal Shearing Machine

Sheet Metal Shearing Machine

-

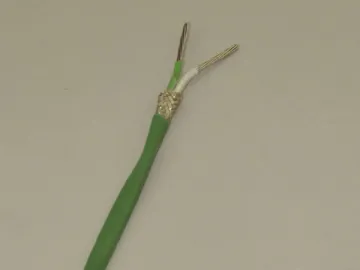

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.43mm)

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.43mm)

-

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x24/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x24/0.2mm)

-

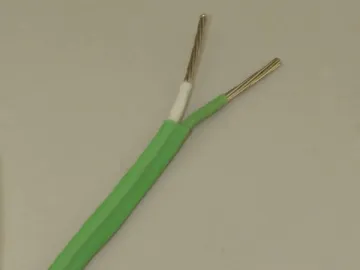

KX Thermocouple Extension Wire(FEP Insulated Wire 2x32/0.2mm)

KX Thermocouple Extension Wire(FEP Insulated Wire 2x32/0.2mm)

-

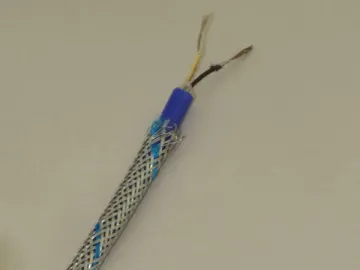

JX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.2mm)

JX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.2mm)

-

CNC H-Beam Beveling Machine

CNC H-Beam Beveling Machine

-

TPPD103 / TPPD104 CNC Hydraulic Punching Drilling Machine

TPPD103 / TPPD104 CNC Hydraulic Punching Drilling Machine

-

TSWZ700 CNC Beam Drilling Line

TSWZ700 CNC Beam Drilling Line

-

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

-

Hydraulic Notching Machine

Hydraulic Notching Machine

-

Compatible AMT Printer Ribbon

Compatible AMT Printer Ribbon