Sheet Metal Shearing Machine

We provide CNC sheet metal shearing machines and hydraulic shearing machines with a complete range of specifications. We are also willing to manufacture shearing machines according to your specific requirements.

Our shearing machine is used for cutting a variety of plates with the rated thickness value. This particular CNC processing equipment can cut steel plates, copper plates, aluminum plates and nonmetal plates. Plates to be cut should fall strictly into the rated value category and have no scars, welding slag or welding lines.

Features

1. Our plate shearer has welded-steel plate construction, a hydraulic transmission system, and nitrogen cylinder for the return stroke. It is easy to operate and has a great shape and reliable performance.

2. It features a fence-like protection device to ensure the safety of the operating staff in the working area.

3. Our CNC sheet metal shearing machine has an alignment lighting device, and the stroke of the top knife rest can have a stepless adjustment.

4. There is an indicator for the gap adjustment of the cutting edge, and it is quick and convenient.

5. The back barrier size and times for cutting both have digital displays.

| Models | Thickness of plate (mm) | Width of plate (mm) | Shearing angle (°) | Times of stroke(time/min) | Back barrier stroke (mm) | Motor power (kw) | Dimension (L×W×H) (mm) |

| 4×2,000 | 4 | 2,000 | 1°30' | 18 | 20-600 | 4 | 2,560×1,400×1,450 |

| 4×2,500 | 4 | 2,500 | 1°30' | 16 | 20-600 | 4 | 3,110×1,430×1,450 |

| 4×3,200 | 4 | 3,200 | 1°30' | 12 | 20-600 | 5.5 | 3,840×1,675×1,620 |

| 4×4,000 | 4 | 4,000 | 1°30' | 10 | 20-600 | 5.5 | 4,640×1,850×1,850 |

| 4×5,000 | 4 | 5,000 | 1°30' | 8 | 20-600 | 7.5 | 5,655×1,850×1,850 |

| 6×2,000 | 6 | 2,000 | 1°30' | 18 | 20-600 | 7.5 | 2,580×1,530×1,600 |

| 6×2,500 | 6 | 2500 | 1°30' | 16 | 20-600 | 7.5 | 3,130×1,530×1,600 |

| 6×3,200 | 6 | 3,200 | 1°30' | 12 | 20-600 | 7.5 | 3,840×1,675×1,620 |

| 6×4,000 | 6 | 4,000 | 1°30' | 10 | 20-600 | 7.5 | 4,630×1,850×1,760 |

| 6×5,000 | 6 | 5,000 | 1°30' | 8 | 20-600 | 11 | 5,690×2,000×2,100 |

| 6×6,000 | 6 | 6,000 | 1°30' | 6 | 20-600 | 11 | 6,715×2,130×2,170 |

| 8×2,500 | 8 | 2,500 | 1°30' | 12 | 20-600 | 11 | 3,148×1,850×1,620 |

| 8×3,200 | 8 | 3,200 | 1°30' | 10 | 20-600 | 11 | 3,848×1,900×1,760 |

| 8×4,000 | 8 | 4,000 | 1°30' | 8 | 20-600 | 11 | 4,648×2,650×1,760 |

| 8×6,000 | 8 | 6,100 | 1°30' | 6 | 20-600 | 15 | 6,900×2,300×1,760 |

| 10×2,500 | 10 | 2,500 | 1°30' | 10 | 20-600 | 18.5 | 3,200×1,850×1,700 |

| 10×3,200 | 10 | 3,200 | 1°30' | 8 | 20-600 | 18.5 | 3,225×1,800×1,940 |

| 12×2,500 | 12 | 2,500 | 2° | 10 | 20-800 | 18.5 | 3,925×1,800×1,940 |

| 12×3,200 | 12 | 3,200 | 2° | 8 | 20-800 | 18.5 | 3,925×1,800×1,940 |

| 12×4,000 | 12 | 4,000 | 2° | 7 | 20-800 | 18.5 | 4,725×2,000×2,040 |

| 12×5,000 | 12 | 5,000 | 2° | 6 | 20-800 | 18.5 | 5,750×2,260×2,240 |

| 16×2,500 | 16 | 2,500 | 2° | 10 | 20-800 | 22 | 3,350×2,000×2,040 |

| 16×3,200 | 16 | 3,200 | 2° | 8 | 20-800 | 22 | 3,225×1,800×1,940 |

| 16×4,000 | 16 | 4,000 | 2° | 7 | 20-800 | 22 | 4,850×2,190×2,250 |

| 20×2,500 | 20 | 2,500 | 2°30' | 6 | 20-800 | 30 | 3,325×2,265×2,200 |

| 20×3,200 | 20 | 3,200 | 2°30' | 5 | 20-800 | 30 | 4,025×2,265×2,350 |

| 25×2,500 | 20 | 2,500 | 3° | 5 | 20-800 | 37 | 3,365×2,260×2,430 |

Links:https://www.globefindpro.com/products/72322.html

-

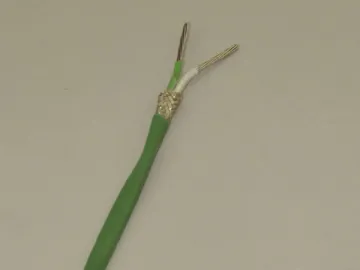

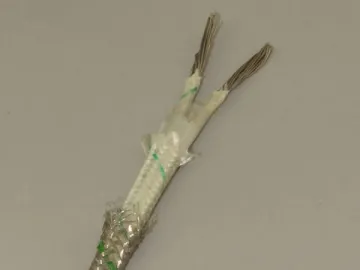

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.43mm)

KX Thermocouple Extension Wire(PTFE Insulated Wire 2x7/0.43mm)

-

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x24/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x24/0.2mm)

-

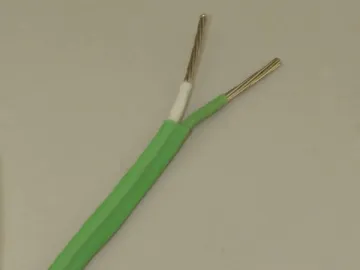

KX Thermocouple Extension Wire(FEP Insulated Wire 2x32/0.2mm)

KX Thermocouple Extension Wire(FEP Insulated Wire 2x32/0.2mm)

-

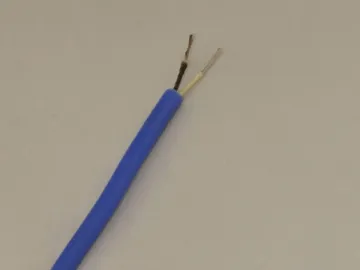

JX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.2mm)

JX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x7/0.2mm)

-

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x16/0.3mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x16/0.3mm)

-

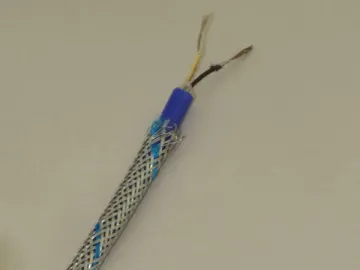

JX Thermocouple Extension Wire(Fiberglass Insulated Silicone Rubber Sheathed Wire 2x7/0.2mm)

JX Thermocouple Extension Wire(Fiberglass Insulated Silicone Rubber Sheathed Wire 2x7/0.2mm)

-

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

KX Thermocouple Extension Wire(Fiberglass Insulated Wire 2x14/0.2mm)

-

TBL2020 CNC Angle Line (Including Structural Steel Punching, Marking, Shearing Machine)

TBL2020 CNC Angle Line (Including Structural Steel Punching, Marking, Shearing Machine)

-

CNC H-Beam Beveling Machine

CNC H-Beam Beveling Machine

-

TPPD103 / TPPD104 CNC Hydraulic Punching Drilling Machine

TPPD103 / TPPD104 CNC Hydraulic Punching Drilling Machine

-

TSWZ700 CNC Beam Drilling Line

TSWZ700 CNC Beam Drilling Line

-

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)

TADM2532 CNC Angle Line (High Speed CNC Drilling and Marking Machine)